Automotive Solutions

Advanced Additive Manufacturing Solutions for Automotive Industry

At Formero, we specialise in providing advanced additive manufacturing solutions tailored for the automotive industry. With our expertise in MJF (Multi Jet Fusion), SLS (Selective Laser Sintering), and FDM (Fused Deposition Modelling) technologies, we offer a range of capabilities to meet the unique demands of automotive applications. From functional prototypes to end-use parts, our solutions deliver exceptional quality, durability, and performance for automotive innovation.

Selective Laser Sintering (SLS)

With SLS technology, we provide automotive designers and engineers the ability to produce complex geometries and durable parts. SLS offers a wide range of materials suitable for automotive applications, including high-performance plastics and composites. From lightweight components to functional parts with excellent heat resistance, SLS empowers automotive manufacturers to create innovative designs with superior strength and reliability.

Benefits of SLS Printing:

- Durable and Heat-Resistant Parts: SLS technology produces robust parts with excellent mechanical properties, making it suitable for automotive applications that require high durability and resistance to temperature variations

- Customisation and Personalisation: SLS allows for the production of customised automotive components, tailored to specific requirements such as ergonomics, fitment, and individual preferences

- Rapid Prototyping for Iterative Design: SLS enables the rapid production of functional prototypes, facilitating iterative design improvements and reducing time to market for automotive manufacturers

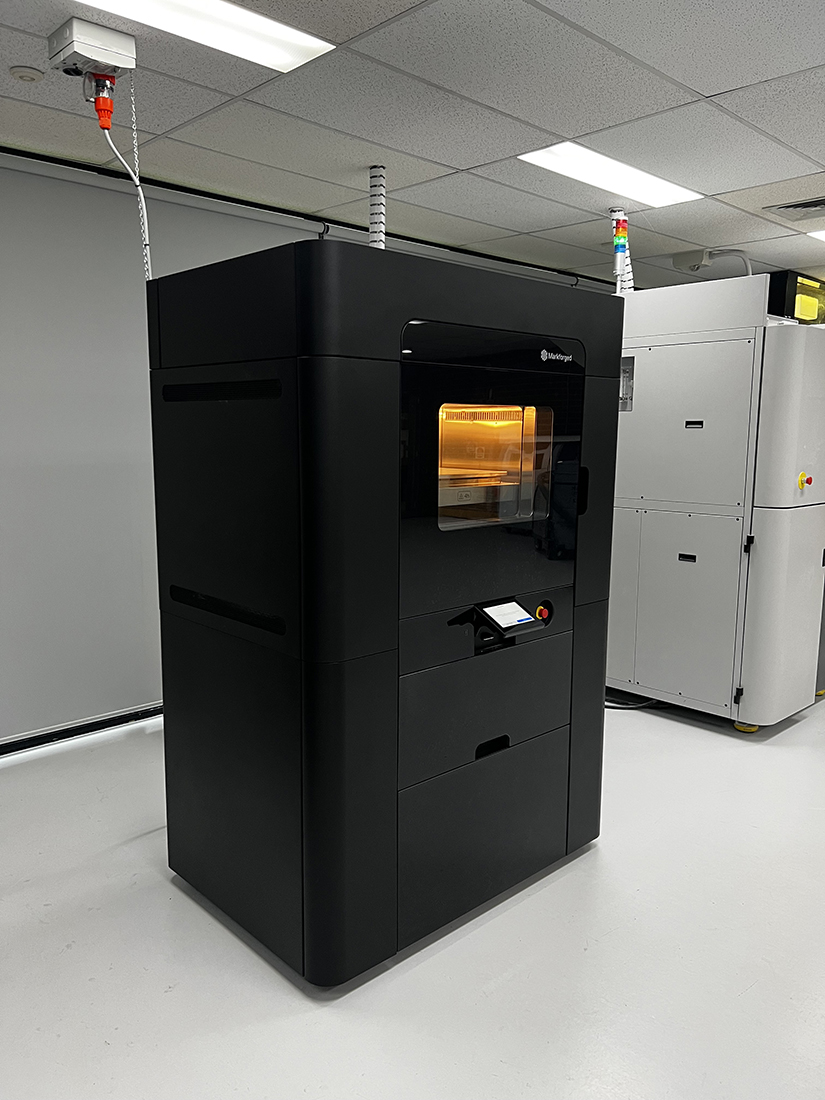

Fused Deposition Modelling (FDM)

Our Markforged FX20 FDM technology combines the versatility of Fused Deposition Modelling with the option of increased strength with Carbon Fiber Reinforcement. This allows for the production of high-strength, lightweight automotive parts with excellent mechanical properties. The ability to integrate carbon fiber reinforcement enables automotive manufacturers to achieve superior strength-to-weight ratios, making it ideal for structural components, jigs, and fixtures within the automotive industry.

Benefits of FDM Printing:

- High-Strength Components: Onyx and Ultem materials naturally provide high strength when printed on their own, however with the option of CFR allows for the production of automotive parts with increased strength-to-weight ratios, providing improved structural integrity and performance

- Enhanced Durability and Toughness: CFR reinforcement adds robustness and impact resistance to the printed parts, making them well-suited for demanding automotive applications that require superior toughness and reliability

- Cost-Effective Manufacturing: a cost-effective solution for producing functional automotive parts with advanced material properties, reducing production costs compared to traditional manufacturing methods

Multi Jet Fusion (MJF)

MJF technology enables the production of high-quality automotive components with excellent strength and surface finish. From interior panels to engine components, MJF delivers precise, functional prototypes and end-use parts with short lead times. Its high accuracy and mechanical properties make it an ideal choice for automotive manufacturers seeking rapid and cost-effective production solutions.

Benefits of MJF Printing:

- Enhanced Design Freedom: MJF enables the production of complex geometries, allowing automotive designers to push the boundaries of innovation and create intricate components with superior functionality and integration

- Weight Reduction: With MJF, automotive manufacturers can achieve significant weight reduction without compromising strength, contributing to improved fuel efficiency, performance, and sustainability

- Short Lead Times: MJF offers rapid production capabilities, allowing automotive companies to accelerate their design iterations, perform quick testing and validation, and expedite the overall product development process.

Supporting the Future of Automotive Innovation

In addition to our commitment to providing advanced additive manufacturing solutions for the automotive industry, we are proud to sponsor Monash University’s Motorsport Program. As a leading initiative in automotive design and performance, this program cultivates the skills and knowledge of the next generation of automotive engineers. Our partnership with Monash Motorsport Program allows us to support and contribute to the development of innovative solutions in the automotive field. Through this collaboration, we empower young talents, foster creativity, and drive the future of automotive engineering.

Wide selection of Materials Available

We offer a wide selection of materials specifically curated for the automotive industry, featuring high-strength polymers, high-temperature polymers, and specialised high-grade materials. Explore our diverse range and find the perfect material to meet the unique requirements of your automotive projects.

Selective Laser Sintering

- DuraForm® PA Plastic

- DuraForm® EX Plastic

- DuraForm® GF Plastic

- DuraForm® HST Composite

- DuraForm® PAx Natural

Multi Jet Fusion

PA 12 (Nylon) known for its toughness, tensile strength, impact strength and ability to flex without fracture.

Why choose Formero for your automotive needs?

At Formero, we understand the entire product development cycle of the automotive industry. Whether you require functional prototypes for testing and validation or end-use parts for production vehicles, our additive manufacturing solutions support your journey from concept to production. With a focus on quality, precision, and efficiency, we ensure that our automotive solutions meet the demanding standards of the industry.

Formero is your trusted partner for additive manufacturing solutions in the automotive industry. With our advanced technologies, expertise, and commitment to quality, we enable automotive manufacturers to accelerate their design iterations, reduce production costs, and bring innovative products to market faster. Contact us today to discuss your automotive additive manufacturing needs and discover how Formero can drive your automotive innovation.

Services Available

Ready to speak with us?

If you have questions please feel free to contact us.