Unlocking Space Innovation

Unlocking space innovation with 3D Printing and Additive Manufacturing

At Formero, we specialise in providing cutting-edge prototyping and additive manufacturing solutions tailored for space projects. Leveraging advanced technologies including MJF (Multi Jet Fusion), SLS (Selective Laser Sintering), and FDM (Fused Deposition Modelling), we offer a comprehensive range of 3D Printing technology, materials and capabilities to meet the unique requirements of the space industry.

Benefits of MJF and SLS

- Durability: Our SLS and MJF processes utilise a wide range of robust materials suitable for space applications, ensuring your parts exhibit high durability and can withstand the demanding conditions of space environments

- Customisation: With SLS and MJF, we offer extensive customisation options, allowing you to tailor parts to meet your specific requirements and design specifications for space components

- Accuracy: The layer-by-layer additive manufacturing process of SLS and MJF ensures exceptional accuracy and precision. Ideal for functional prototypes and production parts

- Fast Turnaround: Our SLS and MJF processes allow for rapid prototyping, enabling quick iterations, efficient design improvements, and fast turnaround times to meet the timelines of your space projects. We can have parts ready in as little as two days

- No Tooling Required: Go straight from prototyping to production with additive manufacturing. Minimise lead-times and tooling costs with our additive manufacturing processes

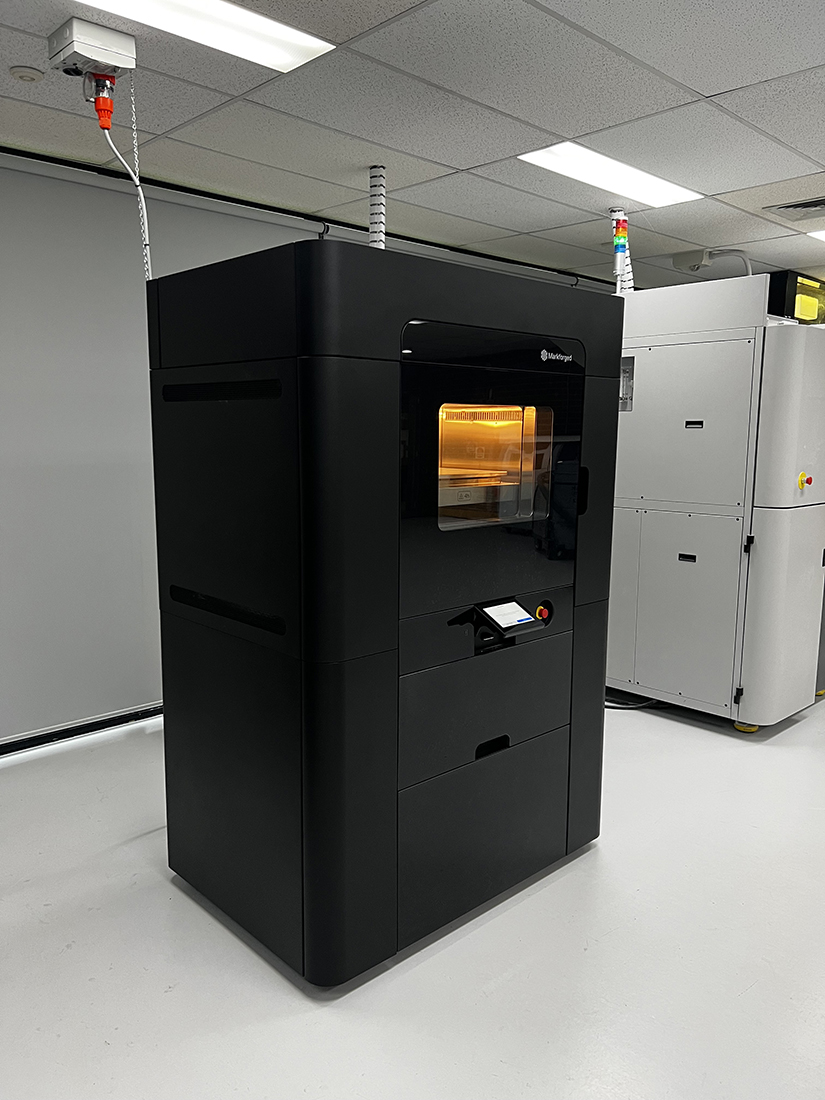

Benefits of FDM with Markforged Printers for Space Prototyping:

- Design Versatility: FDM offers extensive design versatility, allowing for the creation of complex geometries, intricate details, and internal structures, enabling you to bring your innovative space designs to life

- Material Compatibility: We offer a wide range of materials suitable for space applications, including thermoplastics with varying properties such as strength, heat resistance, flexibility, and chemical resistance

- CFR Compatible: Continuous Fibre Reinforcement (CFR) allows us to create high-strength parts by incorporating Carbon Fibre into the printing process

- Lightweight Structures: FDM enables the production of lightweight structures, reducing the overall weight of space components and contributing to fuel efficiency, payload capacity, and overall mission performance

- Functional Testing: Integration of functional features and components is possible, enabling comprehensive testing of space components and systems before final production, thus minimising risks and ensuring reliability

Wide selection of Materials Available

We offer a wide selection of materials specifically curated for space prototyping, featuring high-strength polymers, high-temperature polymers, and specialised aerospace-grade materials. Explore our diverse range and find the perfect material to meet the unique requirements of your space projects.

Selective Laser Sintering

- DuraForm® PA Plastic

- DuraForm® EX Plastic

- DuraForm® GF Plastic

- DuraForm® HST Composite

- DuraForm® PAx Natural

Multi Jet Fusion

PA 12 (Nylon) known for its toughness, tensile strength, impact strength and ability to flex without fracture.

Why choose Formero for your space prototype needs?

Formero is your trusted partner for cutting-edge prototyping and additive manufacturing solutions tailored specifically for space applications. With our expertise in SLS, MJF, and FDM technologies, including the utilisation of ULTEM and CFR compatibility, we offer versatile options to meet your specific requirements. Whether you need rapid prototyping for design validation or full-scale additive manufacturing for space components, our advanced capabilities and materials ensure precision, reliability, and durability. Contact us today to discuss your space prototyping and additive manufacturing needs and discover how Formero can take your space projects to new heights.

Services Available

Ready to speak with us?

If you have questions please feel free to contact us.