Rapid Prototyping

Concepts into Tangible Prototypes

At Formero, we understand that in today’s fast-paced business landscape, time is of the essence when bringing your ideas to life. That’s why we specialise in Rapid Prototyping, which allows us to quickly transform your concepts into tangible prototypes using cutting-edge 3D Printing technologies.

Our team of highly experienced and skilled manufacturers are dedicated to precision and efficiency, streamlining Rapid Prototyping from concept to reality. We pride ourselves on a collaborative approach with our customers, and we are committed to helping your Rapid Prototyping project be successful.

The key difference when choosing Formero for your Rapid Prototyping is that we are able to offer a full range of 3D Printing and Additive Manufacturing technologies, including Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), Fused Deposition Modelling (FDM) and Digital Light Processing (DLP), to help you create high-quality prototypes that meet your exact specifications. Our 3D Printing and Rapid Prototyping services are ideal for creating complex geometries, intricate designs, high quality finishes and functional prototypes.

Our Rapid Prototyping Process

Rapid prototypes are an important part of the product development process – especially if your goal is to get your product to market quickly. Rapid prototyping technology makes it possible for you to quickly and accurately create a prototype of your product, allowing you to test and validate the concept before moving on to mass production.

Our rapid prototyping processes at Formero go beyond simply creating a physical representation of your product. We strive to understand the design intent, functionality, and end-use of the rapid prototype to ensure that it meets your requirements and helps you achieve your desired outcome.

Rapid Prototyping Methods

At Formero, we embrace a variety of rapid prototyping techniques that cater to different needs and project scopes. Each rapid prototyping technique is carefully chosen to ensure that your prototype closely mimics the final product, allowing you to gain valuable insights and make necessary improvements before heading into production. Now, let’s take a closer look at the various Rapid Prototyping methods we utilise.

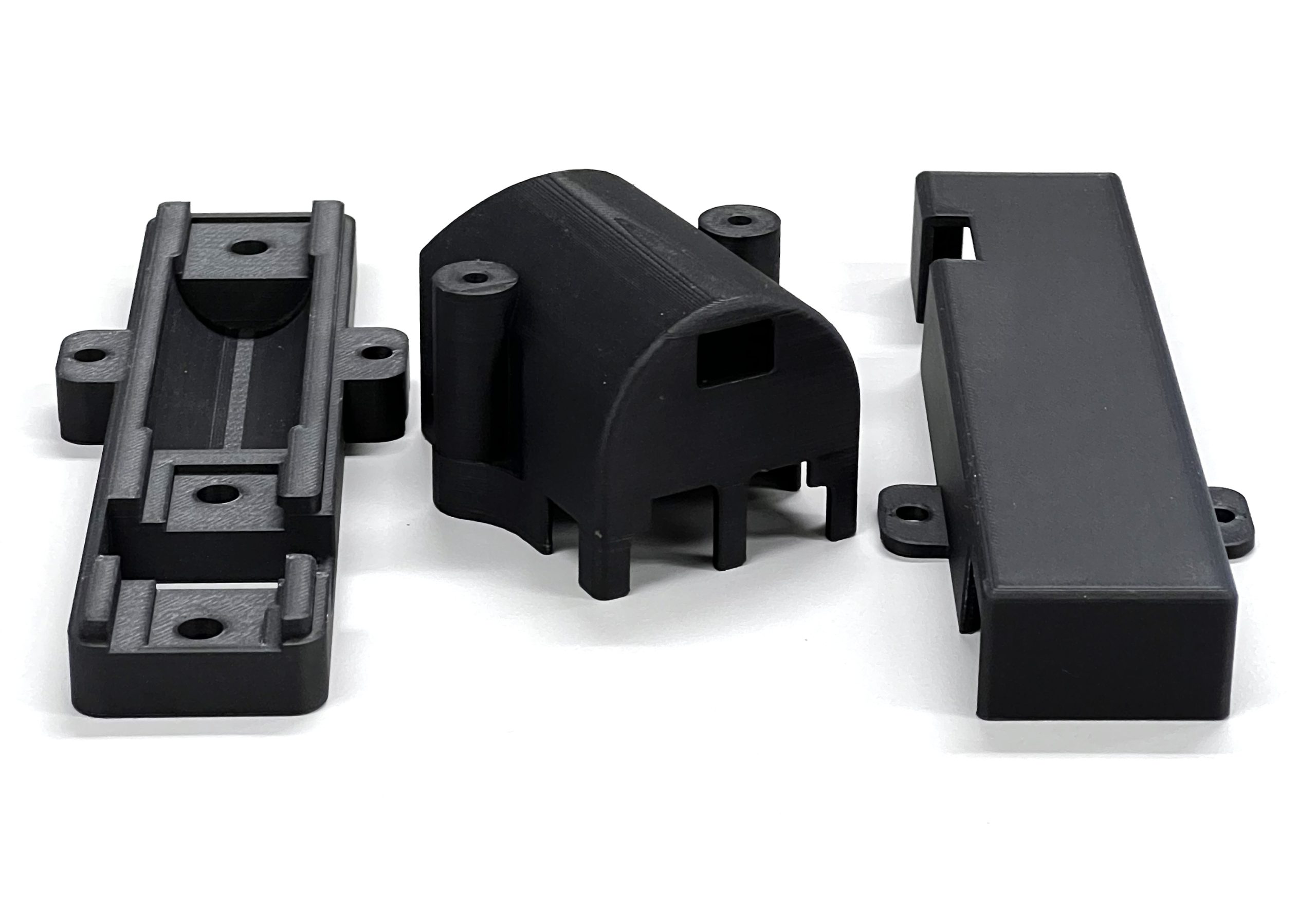

SLS Technology: Geometrically Complex Components

Selective Laser Sintering (SLS) is ideal for creating prototypes, custom production parts, hinges, snaps, clips and/or parts exposed to high temperatures or caustic chemicals. Particularly when you need tough and geometrically complex components.

When using SLS 3D printing technology, your designs are not constrained by the need to adhere to draft angles and consistent thicknesses. This enables a number of design improvements over traditional part manufacturing. It also allows for lighter components, faster manufacturing, and the ability to produce multiple parts at the same time.

MJF Technology: Detailed & Complex Parts

Multi Jet Fusion (MJF) is an industrial 3D printing process ideally suited for the rapid manufacture of prototype parts. The end-use parts exhibit isotropic properties in all axes, which translates to consistent mechanical properties throughout the part. This results in as printed parts that require little post-processing, and parts exhibit many properties including vibration dampening, durability and water-tightness.

An MJF part is comparable to parts created by injection moulding and is stronger than components created by fused deposition modelling, which is why MJF 3D Printing technology is an ideal solution for Rapid Prototyping of functional parts in many industries.

DLP Technology: Speed, Efficiency & Excellence

In the realm of Rapid Prototyping, time is often the differentiator. Our Digital Light Processing (DLP), often referred to as Figure 4, technology ensures not just speed but a blend of efficiency and accuracy. Your visions come to life rapidly without compromising on the high standards your project demands.

DLP is a 3D printing technology that projects a mask of a whole cross-sectional layer at a time. This process can print significantly faster than SLA technology. DLP printing is ideal for creating parts with complex geometries, undercuts, and fine details. However, DLP feature a smaller print bed and is best suited for smaller prototype prints.

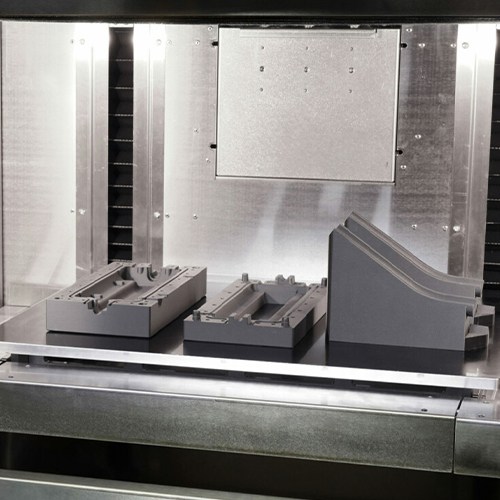

FDM Technology: Industrial-grade Applications

Fused Deposition Modelling (FDM) 3D printing, also known as Fused Filament Fabrication (FFF), is renowned for its versatility and cost-effectiveness. At Formero, we utilise the latest technology from MarkForged. One of the standout features of the MarkForged FX20 is its ability to incorporate Continuous Fibre Reinforcement (CFR). CFR is when a continuous strand of fibre is laid into the part through a secondary nozzle. This provides end-use parts with exceptional mechanical properties.

FDM 3D printing is ideal for a wide range of Rapid Prototyping applications, with its ability to create functional prototypes, end-use parts, and even jigs and fixtures. Industries rely on FDM for rapid iteration and design validation.

SLA Technology: Precision at its Finest

Stereolithography (SLA) ensures precision and detail in every layer, creating prototypes with exceptional accuracy and a wide range of materials available. Whether you’re refining intricate designs or testing complex geometries, our SLA technology delivers results that meet the highest standards. At Formero, we offer 3 different material options for your Rapid Prototyping needs including a clear plastic and a durable ultra-tough plastic.

SLA uses a precise and high-powered laser to trace the shape of each layer into a bed of liquid resin. This process produces parts with smoother surface resolution, making it ideal for applications that need detailed surface resolution.

Ready to speak with us?

If you have questions please feel free to contact us.

Rapid Prototyping (FAQ)

Rapid Prototyping is the iterative process of creating a physical model or prototype of an object using a combination of several techniques and technologies such as 3D printing and additive manufacturing. The process often involves taking a digital design of the object and breaking it down into thin layers, which are then printed one layer at a time to create a three-dimensional object. This technique allows for quick and efficient production of prototypes, allowing for a faster iteration, design testing and validation.

Rapid tooling is an application of rapid prototyping where complex parts that are expensive or needed urgently are made using rapid prototyping and used as a tool in another process. 3D printed tools can be great for functional testing, keeping the actual manufacturing process and future use of the product in mind.

Rapid prototyping is a technique that utilizes 3D printing technologies, including SLA, SLS, MJF, FDM, and DLP, to quickly produce physical prototypes of your design. It allows you to assess and refine your product early in the development phase, saving time and costs associated with traditional prototyping methods.

Formero provides a range of 3D printing technologies, such as SLA, SLS, MJF, FDM, and DLP. The choice depends on factors like material requirements, accuracy, and production speed. Our experts can guide you in selecting the most suitable technology based on your project specifications.

Formero offers a variety of materials for rapid prototyping, including plastics, resins, and metals. The choice of material depends on factors like mechanical properties, surface finish, and cost. Our team can assist you in selecting the optimal material based on your project’s functional and aesthetic requirements.

The turnaround time for your rapid prototyping order depends on factors such as the complexity of the design, chosen 3D printing technology, material and finish. We strive to deliver prototypes as quickly as possible without compromising quality this can range from 2-5 days. Our team can provide you with a more accurate estimate based on your specific project details.