Fused Deposition Modelling (FDM)

FDM – Fused Deposition Modelling

Fused deposition modelling (FDM) 3D printing, also known as Fused Filament Fabrication (FFF), is an Additive Manufacturing (AM) process. In this method, objects are constructed layer-by-layer using a thermoplastic filament that is extruded through a heated nozzle. FDM technology is renowned for its versatility and cost-effectiveness.

FDM 3D printing is ideal for a wide range of applications, from aerospace and automotive to healthcare and manufacturing, FDM plays a pivotal role in modern industrial processes. Its ability to create functional prototypes, end-use parts, and even jigs and fixtures has revolutionised the way products are developed and brought to market. Industries rely on FDM for rapid iteration, design validation, and efficient production, resulting in reduced lead times and costs.

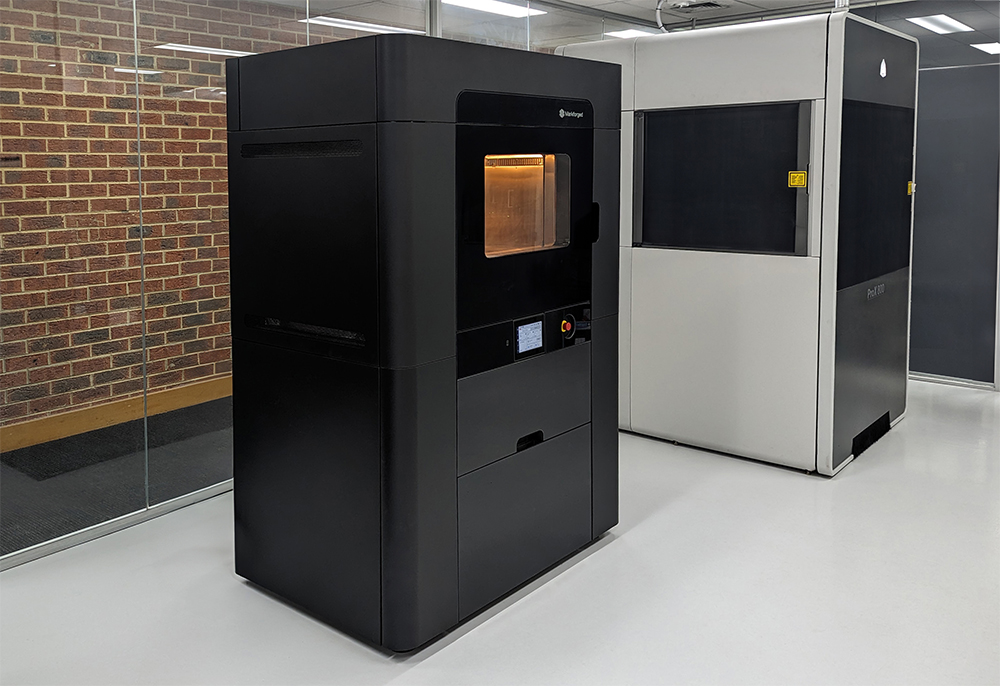

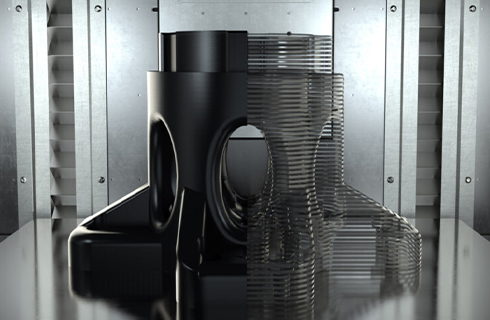

The MarkForged FX20 Advantage

At Formero, for our FDM 3D Printing we operate the MarkForged FX20 printer, a symbol of cutting-edge innovation in additive manufacturing. This printer excels in producing parts that meet the highest standards of strength, repeatability, speed, and quality. With the MarkForged FX20, you can expect consistent, repeatable results, making it an invaluable asset for industrial-grade applications.

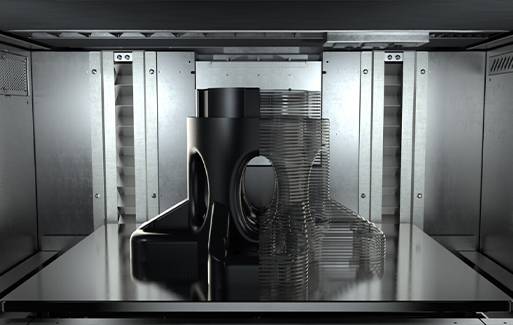

Continuous Fibre Reinforcement (CFR): Unparalleled Strength and Quality

One of the standout features of the MarkForged FX20 is its ability to incorporate Continuous Fibre Reinforcement (CFR) technology. CFR is a continuous fibre reinforcement that is integrated into parts during the printing process. Through a secondary nozzle on the Markforged composite printhead, the carbon fibre is strategically laid down within the inner structure of parts, enhancing their strength and durability. Unlike standalone carbon fibre printing, CFR is used to reinforce components made from composite base materials like Onyx FR, resulting in exceptional mechanical properties.

Materials Available.

Onyx™

Onyx™ — MarkForged’s flagship Composite Base material — is a micro carbon fibre filled nylon that yields accurate parts with near flawless surface finish. Few materials have the versatility of Onyx; it offers high strength, toughness, and chemical resistance when printed alone, and can be reinforced with Continuous Fibres to yield aluminium-strength parts.

Applications

- Plastic Part Replacement

- Housings

- Sensor Mounts

- Cosmetic Prototypes

Technical Specs

| Tensile Stress at Yield: | 40 MPa |

| Tensile Strain at Break: | 25% |

| Flexural Strength: | 71 MPa |

| Izod Impact – notched: | 330 J/m |

| Colour: | Black |

| Build Size (WxDxH): | 525x400x400 mm |

| Layer Thickness: | 0.125 mm |

For more technical data download the material data sheet.

Onyx FR™

Certified UL 94 V-0 rated flame-retardant micro carbon fibre filled nylon.

Onyx FR is a flame-retardant variant of Onyx designed for use in applications where parts must be non-flammable. The material earned a UL Blue Card, and is considered V-0 (self extinguishing) at thicknesses greater than or equal to 3mm. It can also be reinforced with Continuous Fibre.

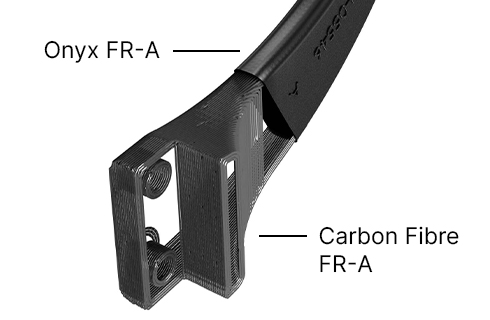

Now Available with Traceability with Onyx FR-A

New FR-A materials establish lot-level material traceability and pass the test suite necessary for qualification under 14 CFR 25.853 for most 3D-printable parts.

Onyx FR-A and Carbon Fibre FR-A are purpose-built for the requirements of the aerospace, transportation and automotive industries.

Applications

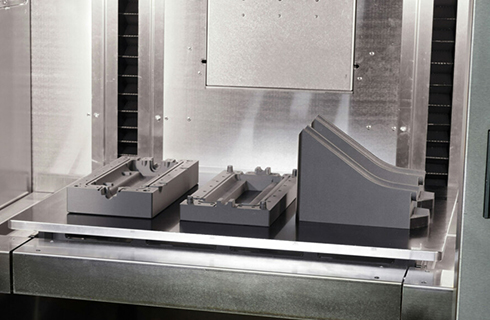

- Weld Fixturing

- Aerospace Clips & Brackets

- Laser Marking Fixtures

- Energy/Electrical Brackets & Fixtures

Technical Specs

| Tensile Stress at Yield: | 41 MPa |

| Tensile Strain at Break: | 18% |

| Flexural Strength: | 71 MPa |

| Izod Impact – notched: | – |

| Colour: | Black |

| Build Size (WxDxH): | 525x400x400 mm |

| Layer Thickness: | 0.125 mm |

For more technical data download the material data sheet.

ULTEM™ 9085

Ultra high performance PEI thermoplastic compatible with continuous carbon fibre

ULTEM™ 9085 is Markforged’s first high temperature printing polymer. It’s an extremely durable thermoplastic that exhibits excellent flame, smoke, and toxicity (FST) characteristics. Usable in production aerospace applications, ULTEM™ Filament brings Markforged’s CFR technology to a new realm of parts.

Applications

- High Temperature Tooling

- Aircraft Interior Panelling

- Aircraft Brackets, Handles, and Knobs

- Custom Ducting

- Composite Moulds and Layup Tools

Technical Specs

| Tensile Stress at Yield: | 68 MPa |

| Tensile Strain at Break: | 5.5% |

| Flexural Strength: | 105 MPa |

| Izod Impact – notched: | 70 J/m |

| Colour: | Black |

| Build Size (WxDxH): | 525x400x400 mm |

| Layer Thickness: | 0.125 mm |

For more technical data download the material data sheet.

Carbon Fibre

The backbone of aluminium-strength composite parts

Carbon Fibre is Markforged’s unique, ultra-high-strength Continuous Fibre — when laid into a Composite Base material like Onyx, it can yield parts as strong as 6061-T6 Aluminium. It’s extremely stiff and strong, and can be automatically laid down in a wide variety of geometries by Markforged 3D printers. A special Carbon Fibre variant is compatible with ULTEM™ 9085 Filament.

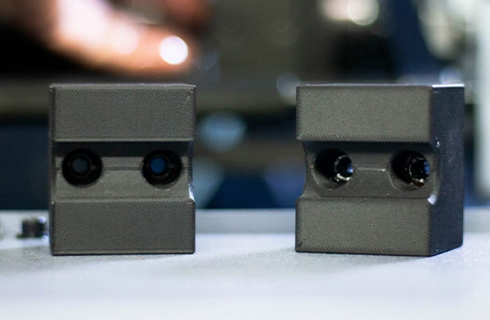

Applications

- High-Strength Tools & Fixtures

- Brackets & Mounts

- Inspection/CMM Fixturing

- Bespoke End-Use Parts

- Functional Prototypes

Technical Specs

*When printed with Onyx

| Tensile Stress at Yield: | 800 MPa |

| Tensile Strain at Break: | 1.5% |

| Flexural Strength: | 540 MPa |

| Izod Impact – notched: | 960 J/m |

| Colour: | Black |

| Build Size (WxDxH): | 525x400x400 mm |

| Layer Thickness: | 0.125 mm |

For more technical data download the material data sheet.

Carbon Fibre FR

The backbone of flight-ready 3D Printed composites

Carbon Fibre FR is a flame-retardant variant of Markforged’s unique, ultra-high-strength Continuous Carbon Fibre — when used to reinforce a Composite Base material like Onyx FR, it can yield parts as strong as 6061-T6 Aluminium. It’s extremely stiff and strong, and can be precisely laid down in a wide variety of geometries. Trace curved features, reinforce holes, and mimic unidirectional fibre layups.

Onyx FR-A and Carbon Fibre FR-A are purpose-built for the requirements of the aerospace, transportation and automotive industries. FR-A materials establish lot-level material traceability and pass the test suite necessary for qualification under 14 CFR 25.853 for most 3D-printable parts.

Applications

- Cabin Components

- Brackets & Mounts

- MRO & Spare Parts

- End-Use Parts

- Functional Prototypes

Technical Specs

*When printed with Onyx

| Tensile Stress at Yield: | 760 MPa |

| Tensile Strain at Break: | 1.6% |

| Flexural Strength: | 540 MPa |

| Izod Impact – notched: | 810 J/m |

| Colour: | Black |

| Build Size (WxDxH): | 525x400x400 mm |

| Layer Thickness: | 0.125 mm |

For more technical data download the material data sheet.

Frequently Asked Questions (FAQ)

Fused Deposition Modelling (FDM) is an additive manufacturing technique that constructs 3D objects by melting and extruding thermoplastic materials in layers. This method is extensively utilised for rapid prototyping and manufacturing functional components.

The Markforged FX20 significantly elevates the FDM printing process by introducing industrial-grade capabilities. It brings about enhanced material options, particularly for producing parts with high strength and flame resistance. The FX20 also introduces the innovative feature of utilising continuous fibre reinforcement within printed parts. This advancement results in parts that possess exceptional strength, rendering them ideal for challenging applications like aerospace and automotive industries.

The Markforged FX20 FDM printing service offers a range of benefits. It delivers parts with outstanding mechanical properties, notably high strength and stiffness. Additionally, the service ensures excellent surface finish for the printed parts, all within a cost-effective price range.

The Markforged FX20 FDM printing service is advantageous for a range of industries that demand durable, robust, and dependable parts. These industries encompass aerospace, automotive, manufacturing, robotics, and any sector that necessitates components built to industrial standards.

Continuous Fibre Reinforcement (CFR) within FDM printing refers to the practice of integrating uninterrupted strands of reinforcing material, such as carbon fibre, directly into the thermoplastic material during the printing process. This integration substantially enhances the mechanical attributes and performance of the printed parts.

Formero focuses on high-performance FDM materials. Although numerous grades of FDM materials are prevalent in the fabber and maker communities, Formero currently provides three specialty materials with our FDM service. These materials are Onyx, Onyx FR, and ULTEM. These options are well-suited for a diverse array of applications and are also compatible with our Continuous Fibre Reinforcement (CFR) printing solution.

Opting for FDM brings several advantages to the table. FDM is recognised for its straightforward process, economical nature, and rapid production of functional prototypes. It’s versatile and applicable across various uses, making it perfect for generating concept models, crafting jigs and fixtures, and manufacturing end-use components.

The precision achievable through FDM printing is influenced by multiple factors such as layer height, printer specifications, and the complexity of the part’s geometry. Specifically, the Markforged FX 20, which we employ, is capable of printing with a layer thickness of 0.125mm. This contributes to the overall precision of the printed components.

Absolutely, FDM-printed parts can undergo post-processing and finishing procedures. Depending on your specific needs, you have a variety of options for post-processing, such as sanding, bead blasting, tumbling, painting, and even incorporating threaded inserts, among others. This flexibility allows you to refine the appearance and functionality of your FDM-printed components as required.

Yes, particularly for FDM parts featuring overhangs, bridges, or intricate geometries, build supports are often necessary. These supports are crucial in preventing deformation or collapse while the printing is in progress. After the printing is done, these supports are removed. You don’t need to worry about this process as we handle the setup and subsequent removal of supports during both the printing and post-processing phases.

Ready to speak with us?

If you have questions please feel free to contact us.