Additive Manufacturing Services

Leading the way in Additive Manufacturing

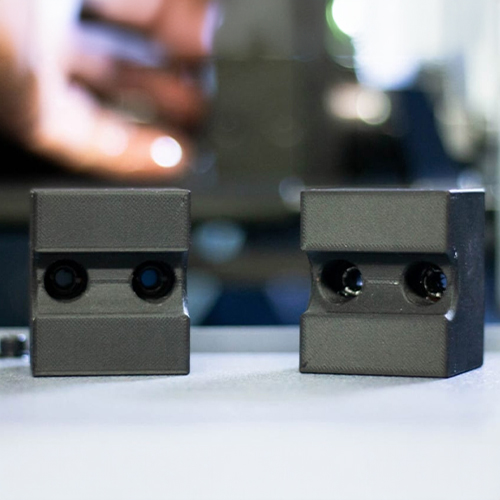

As Australia’s largest and most advanced Additive Manufacturing Service Bureau, we are committed to bridging the gap between 3D printing your prototypes and scaling up to large-scale production, including services like Injection Moulding. We offer industry-leading additive manufacturing technologies such as Multi Jet Fusion (MJF), Selective Laser Sintering (SLS), Fused Deposition Modelling (FDM) and Digital Light Processing (DLP).

These cutting-edge technologies, combined with our range of production-grade materials, are ideal for creating functional, high-quality components in quantities ranging from 100 to 2,000 units.

When you choose Formero for your Additive Manufacturing needs, you can be assured that your parts will be manufactured to the highest standard at our Melbourne based facility. With ISO 9001 Certification we guarantee unmatched precision and reliability in every component. You can also be assured that your Intellectual Property is secure with all parts printed locally in Australia.

Benefits of Additive Manufacturing with Formero.

Customisation

Tailor your products to specific requirements, offering personalised solutions for your projects.

Cost-Effective

Reduce production costs by eliminating the need for complex tooling and moulds, especially for high-volume manufacturing.

Complex Geometries

Create intricate and complex designs that traditional manufacturing methods simply can’t replicate.

Speed & Time-to-Market

Additive manufacturing can drastically reduce lead times, allowing you to get their products to market faster.

Additive Manufacturing Services.

Additive Manufacturing Materials.

Our range of Additive Manufacturing materials encompasses a wide variety of properties and characteristics, allowing us to create parts that meet your exact specifications. For more information on our full range of materials you can view our materials page or visit each service individually. Some materials we use for Additive Manufacturing include:

- Nylon 11 & Nylon 12

- Glass Filled Polyamide (Nylon)

- Fiber-reinforced Composites (Nylon)

- Flame Retardant Materials

- Nylon Copolymers

Benefits of Additive Manufacturing.

Unlike most conventional manufacturing methods, Additive Manufacturing presents numerous benefits that make it the preferred choice for many industries. These include:

- Greater design flexibility: While many traditional manufacturing processes are limited by complexity and geometrical constraints, Additive Manufacturing allows for more intricate designs to be created with ease.

- Faster production: Additive Manufacturing allows customers to skip the timely process of creating costly injection mould tooling. With Formero, it also allows Australian customers to avoid length delivery times.

- Reduced waste: With additive manufacturing, only the necessary material is used, significantly reducing waste.

- Lighter and stronger parts: The layered construction of parts in additive manufacturing results in stronger and lighter products, making it ideal for industries such as aerospace and automotive.

- Customisation: Additive Manufacturing allows for the creation of highly customised products that cater to specific requirements, making it a popular choice for industries such as medical and orthotics.

- Cost-effective: With no need for complex tooling and moulds, Additive Manufacturing can be a more cost-effective option for low-volume or custom designs.

Ready to speak with us?

If you have questions please feel free to contact us.

Frequently Asked Questions (FAQ)

While STL stands out as the standard for 3D Printing, we can also handle a variety of other 3D formats. These include IGS/IGES, STP/STEP, Parasolid ACIS, Solidworks, OBJ, VRML, FBX, among others.

All Additive Manufacturing conducted by Formero takes place at our state-of-the-art printing facility in Nunawading, Victoria. We boast an extensive array of cutting-edge technologies and materials, setting the industry standard in Australia. Our facility is equipped with 12 professional and production grade printers and dozens of material choices.

While you can quickly acquire pricing information using our online quoting system. For Additive Manufacturing quantities, we suggest speaking with our team so that we can discuss pricing brackets and delivery schedules for appropriate pricing. Our team can be contact via email at sales@formero.com.au or give us a call at +61 3 8899 7280.

Yes, we can ship orders anywhere in the world. Please contact our team for a shipping cost.

With our 3D Printing service, you have the option to order as few as 1 item. However, when we talk about Additive Manufacturing we are referring to quantities of over 200.

The lead times vary based on the quantity of parts. the specific technology, material, and post-processing preferences for each job. For Additive Manufacturing lead times, it is best to speak with our sales team.

We provide a selection of more than 20 diverse materials for you to choose from. However, when it comes to Additive Manufacturing the list of appropriate materials narrows. If you’re uncertain about which material aligns best with your project’s specifications, our team is readily available to engage in a discussion and propose a material that will be suitable for your project’s requirements.

We handle a diverse array of confidential and proprietary information from both small and well-known clients on a daily basis. Rest assured, you retain ownership of your data. We solely utilise it for estimating, constructing, and reviewing projects tailored to your needs. Your customer data and part files are strictly kept within our services and aren’t shared externally. Our server and network housing the data are secured by a firewall, with access limited to authorised personnel only.

Yes, we provide a mutual Non-Disclosure Agreement that can be executed by both parties. If you require us to sign an NDA that you provide, please note that we will need to evaluate it before signing, and this evaluation process may take a few days.