QuickCast

QuickCast Service

QuickCasting is a specialised method for creating investment casting patterns using SLA (Stereolithography) 3D printing. This approach creates rapid production of precise patterns, ranging from small to large sizes, with high-quality finishes and tight tolerances.

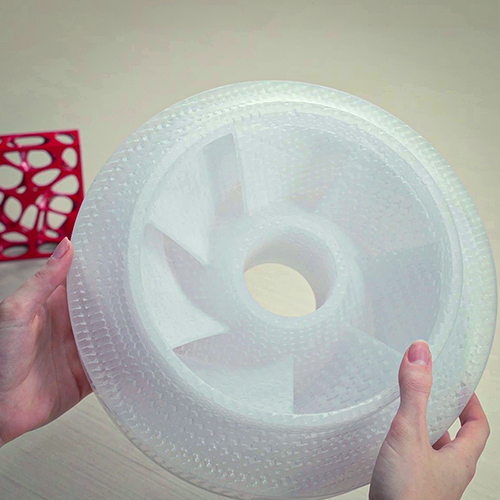

Formero’s QuickCast patterns feature a hollow structure with an internal hexagonal support, providing strength and allowing for easy drainage and collapse during thermal expansion, which prevents shell cracking. QuickCasting offers a cost-effective and time-efficient alternative to traditional investment casting patterns, producing smooth-surfaced, lightweight parts suitable for various applications.

How Formero Can Help

At Formero, we offer expert SLA 3D printing services to create high-quality QuickCast patterns. Our team of highly skilled professionals have extensive experience in SLA 3D printing and QuickCasting, ensuring accuracy and efficiency in every project. With a proven track record of successful projects, we have established a reputation for delivering reliable and accurate casting patterns that exceed industry standards.

Our commitment to rigorous quality control ensures that every pattern meets the highest standards of accuracy and finish. By choosing Formero, you are partnering with a trusted leader in 3D Printing, dedicated to helping you achieve optimal results in your investment casting projects.

QuickCast Advantages

- Precision: QuickCast produces highly accurate patterns, minimising errors and ensuring the final casting meets precise specifications. This level of accuracy is crucial for applications requiring tight tolerances and detailed features.

- Speed: The rapid production capabilities of SLA 3D printing allow QuickCast patterns to be created much faster than traditional methods. This reduces lead times and accelerates the overall production process, enabling quicker turnaround for projects.

- Complexity: QuickCast can create intricate designs that are difficult or impossible to achieve with conventional techniques. This ability to produce complex geometries opens up new possibilities for design innovation and functional optimisation.

- Cost-Effective: By eliminating the need for expensive tooling, QuickCast significantly lowers production costs. This cost-effectiveness is particularly beneficial for low to medium volume runs, making high-quality casting patterns accessible and affordable.

QuickCast Applications

QuickCasting is ideal for various industries, including:

- Aerospace: Producing lightweight, high-strength components.

- Automotive: Rapid prototyping and production of complex engine parts.

- Medical Devices: Ensuring precise and reliable components.

- Consumer Products: Creating intricate designs quickly and efficiently.

- Industrial Machinery: Providing durable and accurate patterns for rigorous use.

QuickCast vs. Traditional Investment Casting

- Lead Time: QuickCast significantly reduces the time required for pattern creation, providing a faster route from design to finished product. This accelerated process is crucial for meeting tight deadlines and responding to market demands swiftly.

- Complexity: The ability to produce highly complex and detailed designs sets QuickCast apart from traditional methods. This capability enables manufacturers to achieve greater design flexibility and optimise part functionality without the constraints of traditional casting techniques.

- Flexibility: QuickCast patterns are easier to modify and iterate, allowing for rapid design changes and improvements. This flexibility is particularly advantageous during the prototyping phase, where multiple iterations may be necessary to achieve the desired result.

- Cost: For low to medium volume production runs, QuickCast is more cost-effective than traditional methods. The reduction in tooling costs and faster production times result in significant savings, making high-quality casting accessible to a broader range of applications and industries.

Related Case Studies.

QUICKCAST™ Patterns

Showcasing how we helped Vaupell create metal parts more efficiently using QuickCast, a technology that creates a ceramic mould from a 3D printed wax pattern.

Read MoreReady to speak with us?

If you have questions please feel free to contact us.