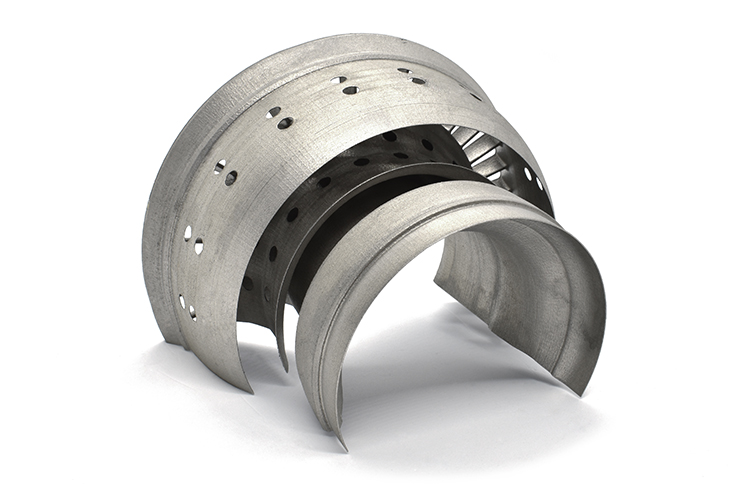

Metal 3D Printing (SLM)

Metal 3D Printing Service

Through industry partners, Formero offers state-of-the-art 3D Metal Printing services utilising Selective Laser Melting (SLM) technology. This advanced manufacturing process allows us to create complex and highly precise metal parts. We understand that 3D printing metal is often difficult, expensive, and slow, so we approach each project with meticulous attention to detail and a commitment to delivering the highest quality results.

How SLM Printing Works

Selective Laser Melting (SLM) is an additive manufacturing process that uses a high-powered laser to melt and fuse metallic powders layer by layer. The process starts with a digital 3D model, which is sliced into thin layers. The laser selectively melts the powder according to the digital design, building the part layer by layer from the bottom up. This method allows for the creation of intricate geometries that would be impossible to achieve with traditional manufacturing techniques.

Advantages of 3D Metal Printing

3D Metal Printing offers numerous benefits, including:

- Design Freedom: Create complex and intricate designs that are not feasible with conventional manufacturing such as challenging internal passages that could not be produced using conventional manufacturing techniques such as casting or CNC Machining.

- Customisation: Easily produce customised parts tailored to specific needs and applications. This flexibility allows for the production of unique and one-of-a-kind components.

- Material Efficiency: Minimise waste as the process uses only the material necessary to create the part.

- Difficult-to-Form Metal Alloys: Utilise metal alloys that are conventionally very difficult to form, machine, or cast, including Titanium and Inconel.

- Fine Features and Thin Walls: Form fine features and thin walls, less than 0.5mm. Sharp features and fine points may be printable.

- High-Temperature Applications: Suitable for applications requiring high thermal resistance.

- Thermal/Electrical Conductivity: Create parts with excellent thermal and electrical conductivity.

- High Density and Purity: SLM technology offers the best density and purity of the part material, with no binders, sintering, or firing needed.

- Near-Net Parts: Produce near-net shape parts, making it a good alternative to casting.

Disadvantages of 3D Metal Printing

Despite its advantages, 3D Metal Printing also has some disadvantages:

- High Costs: The process can be expensive due to the cost of metal powders and the advanced equipment required.

- Slow Production Speed: As an emerging technology in manufacturing, the inherent challenges of the metal 3D printing process can slow down production and make less predictable when estimating manufacturing timeframes. Each design requires custom printed supports to ensure high-quality results, and these supports may take several iterations to perfect and subsequent removal strategies for supports e.g. wire cutting and machining.

- Increased Post-Procession: Metal 3D Printing requires additional labour intensive post processing when compared to plastic 3D Printing.

- Material Limitations: Not all metals are suitable for 3D printing, and material properties can vary.

- Design Limitations: Components must be well-considered for SLM to work. Unlike plastic 3D printing methods, you can’t rely on support material to make anything possible.

- Surface Finish Variability: Surface finish can vary, dependent on build angle and other factors.

Ensuring High-Quality Results

To ensure the highest quality results, Formero implements rigorous testing procedures for all 3D Printed metal parts. We collaborate with Industry Leading Partners to offer comprehensive testing services, including:

- Tensile Testing: Evaluates the material’s strength and ductility by pulling the sample until it breaks, providing essential data on the material’s behaviour under stress.

- Non-Destructive Testing (NDT): Assesses the integrity of the part without causing damage, using methods such as ultrasonic, radiographic, and magnetic particle testing to detect any internal defects or inconsistencies.

- X-Ray Testing: Uses X-rays to inspect the internal structure of the part, identifying potential flaws that are not visible to the naked eye.

These stringent quality control measures ensure that every part we produce is free from defects and meets the highest industry standards.

Materials We Offer

Formero provides a selection of high-quality metal materials for 3D printing, including:

- Aluminium: Known for its lightweight and excellent thermal conductivity, Aluminum is ideal for applications requiring strength without added weight.

- Titanium: Offers superior strength-to-weight ratio and excellent corrosion resistance, making it suitable for aerospace, medical, and high-performance engineering applications.

- Stainless Steel: Renowned for its strength, durability, and resistance to corrosion and high temperatures, Stainless Steel is perfect for a wide range of industrial and consumer products.

We are also open to discussing other metal materials during the consultation stage to meet specific project requirements.

Ready to speak with us?

If you have questions please feel free to contact us.