3D Printing Large Parts

September 29, 2020

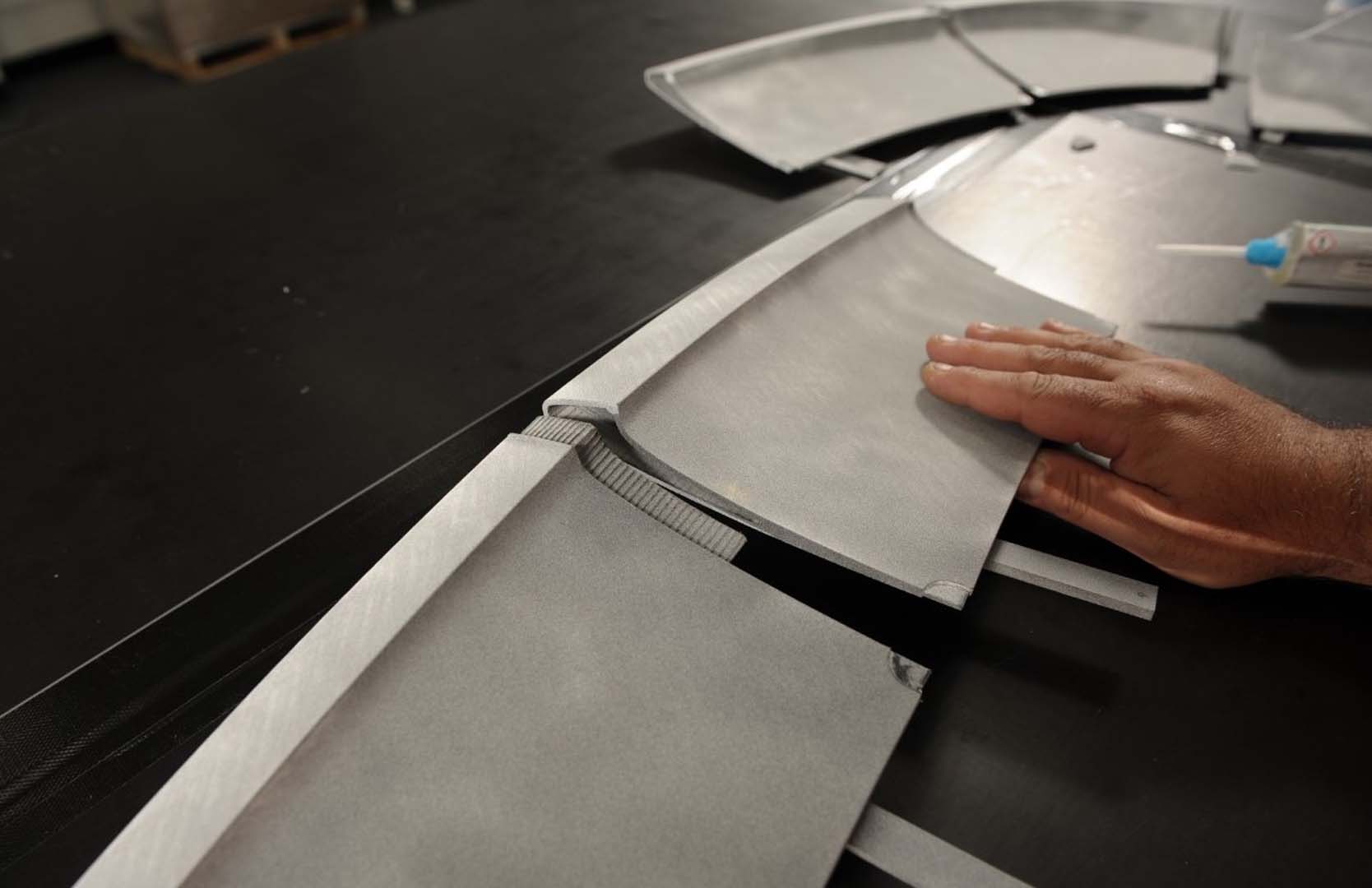

When a large design is beyond the build volume of our 3D printers, the CAD is split into sections and interlocking features are designed within the file. So that when the sections are printed it helps position the parts when bonded together with adhesives.

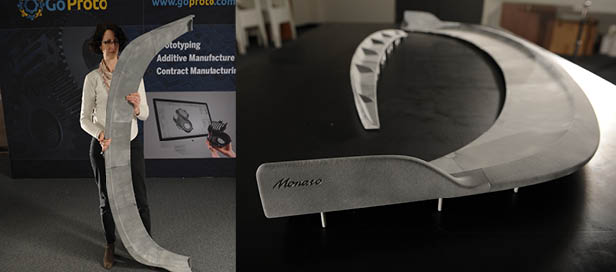

Below are some great MJF examples of large 3D Printed components used for design validation, moulds or end-use applications.

Above: End-use 3D printed automotive component of a rear spoiler and front splitter by Formero.

Above: 3D printed prototype of an automotive dashboard by Skorpion Engineering.

Above: 3D printed aircraft fuselage for pilot testing by DI Labs. The full-size fuselage model was created so the customer could perform internal testing for ergonomics, cockpit design, and operation.