From Concept to Creation: Your Guide to Injection Tooling & Moulding in Australia

February 20, 2024

Do you have a product and need to bring it to life? Injection tooling and moulding might be the solution you’re looking for. This versatile manufacturing process allows you to create high-quality, complex plastic parts with incredible precision and efficiency. This comprehensive guide will assist you through the steps of creating injection tooling and processing the final moulded parts.

What is Injection Tooling & Moulding?

Injection tooling and moulding is a high-precision manufacturing process used to create complex plastic parts in high volumes. It involves two key steps:

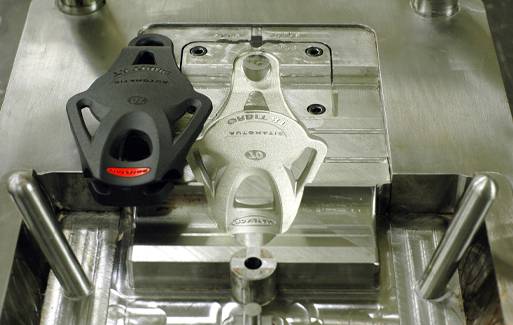

1. Injection Tooling:

This stage involves designing and fabricating a custom mould, typically from hardened steel or other robust materials. The mould features precisely machined cavities that match the exact shape and features of the desired plastic part. This crucial step ensures consistent and accurate part production throughout the process.

2. Injection Moulding:

Molten plastic, carefully selected based on its physical properties and application requirements, is injected under high pressure into the mould. The plastic fills the cavities and cools, solidifying into the final shape of the part. This stage requires precise control of parameters like temperature, pressure, and cooling rate to achieve optimal quality and consistency.

Benefits of Injection Tooling & Moulding:

- High Precision: This process excels at creating complex parts with tight tolerances and intricate details, ideal for demanding applications across various industries.

- High Efficiency: Injection moulding enables the mass production of identical parts with minimal waste, making it cost-effective for high-volume requirements.

- Versatility: This technology accommodates a wide range of plastic and rubber materials, allowing you to choose the optimal material for strength, flexibility, heat resistance, and other properties specific to your needs.

- Durability: The resulting plastic parts are known for their strength and longevity, ensuring product functionality and performance over time.

Our Injection Tooling & Moulding Process

Step 1: Design and Development

It all starts with your vision. Our experienced team in Melbourne, Australia will work closely with you to refine your concept, ensuring it’s optimised for the injection moulding process. We’ll consider factors like material selection, part geometry, and functionality to create a design that is both beautiful and manufacturable.

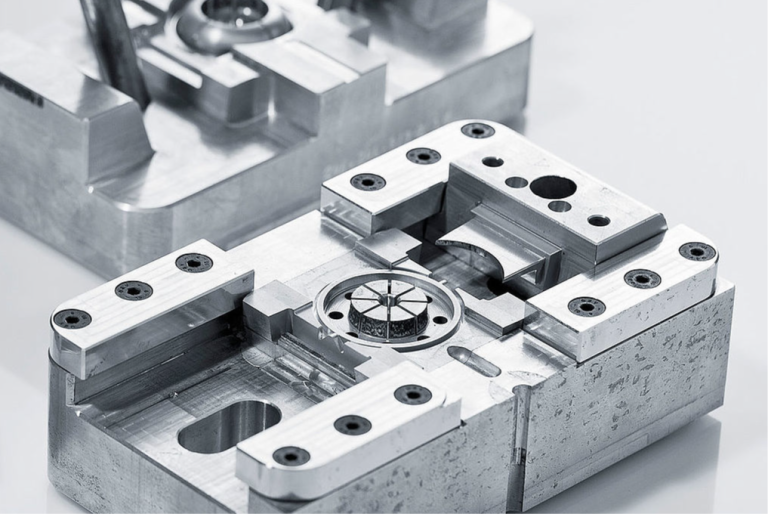

Step 2: Tooling Design and Manufacturing

Once the design is finalised, it’s time to create the mould, the heart of the injection moulding process. Our team of skilled toolmakers will utilise cutting-edge technology and precision engineering to craft a mould that precisely matches your part specifications. This stage involves selecting the right steel type, machining intricate features, and ensuring optimal heat and pressure distribution for consistent, high-quality results.

Step 3: Material Selection

The choice of material plays a crucial role in the final product’s properties. Our material experts will guide you through a wide range of options, considering factors like strength, flexibility, heat resistance, and chemical compatibility. We use only the highest-grade resins from reputable suppliers to ensure your parts meet the strictest quality standards.

Step 4: The Injection Moulding Process

Molten plastic is injected into the heated mould under high pressure, filling every cavity with detail and precision. Once cooled and solidified, the part is ejected, ready for any necessary post-processing steps like finishing, assembly, or packaging.

Step 5: Quality Control and Delivery

At every stage, our team in Australia adheres to stringent quality control procedures. We meticulously inspect each order to ensure it meets your exact specifications and delivers exceptional performance.

The Australian Advantage

Choosing an Formero for your injection tooling & moulding offers several benefits:

- Communication: Enjoy clear communication and local based support from our team throughout the process. Being local also means that we’re working when you’re working.

- Quality and Expertise: Leverage our extensive experience and commitment to using only the highest quality materials and equipment.

- Competitive Pricing: Get access to cost-effective solutions without compromising on quality or service.

Ready to Bring Your Vision to Life?

Whether you’re a seasoned manufacturer or a budding entrepreneur, injection tooling and moulding can be your key to success. Contact us today to discuss your project and unlock the potential of this transformative technology. Together, we’ll turn your concept into a reality, made with precision and quality.

Bonus: White Paper

Download: White Paper | Design for Manufacture Guidelines

Author

Craig Alexander

Craig is a seasoned marketing professional with over 13 years of diverse experience in industries ranging from Asphalt Testing Technology to Environmental Sciences. His extensive background in B2B marketing, coupled with a deep understanding of complex technical fields like Power Tools, Solar & Battery Systems, and Emergency Lighting, uniquely positions him to bridge the gap between advanced manufacturing technologies and market needs. Craig leverages his comprehensive marketing skills to translate intricate manufacturing processes and innovations into clear, compelling narratives, helping businesses of all sizes succeed in both local and international markets.