Quick Turnaround Architectural Models

Quick Turnaround Architectural Models

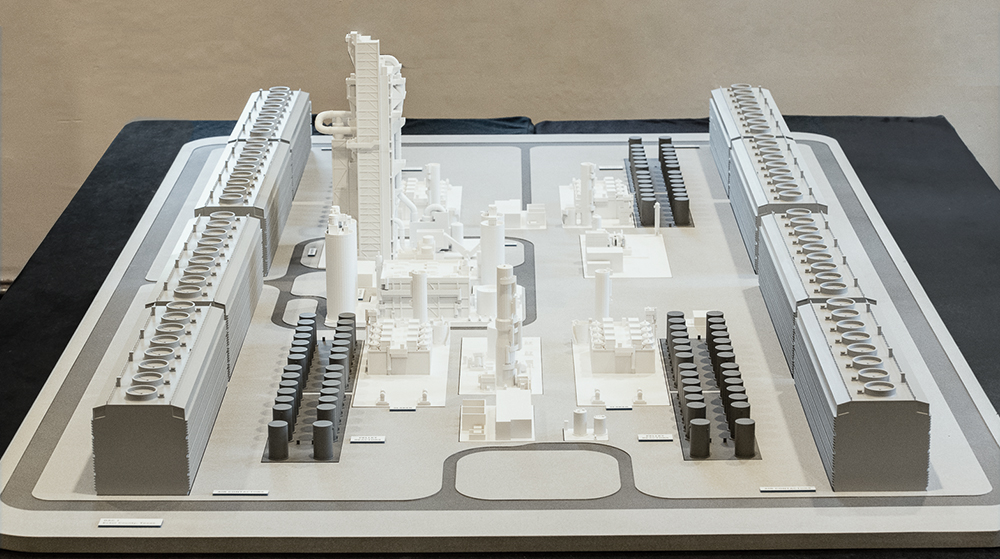

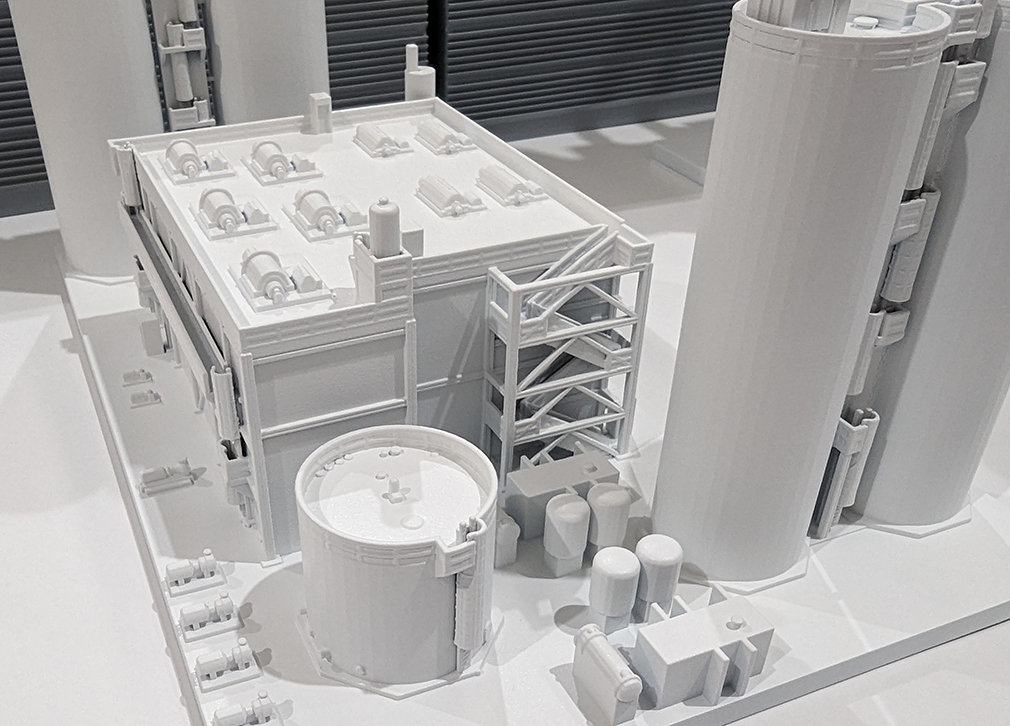

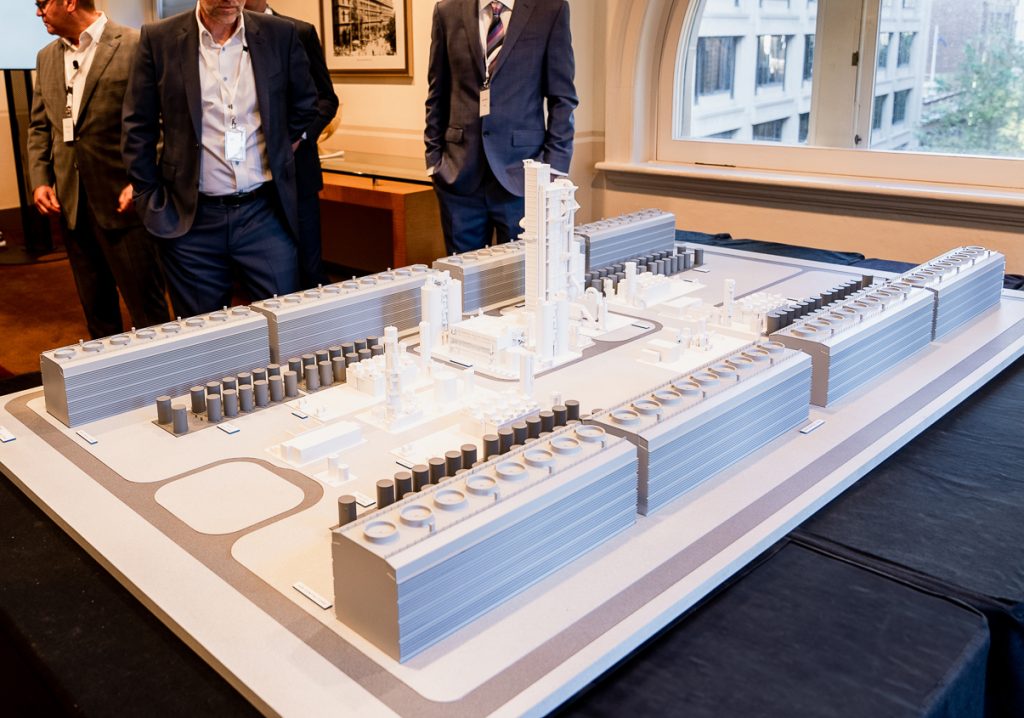

Worley, a professional services company of energy, chemical and resources experts, asked Formero to assist it with the quick printing of architectural models for an upcoming investor day presentation. The model was of a carbon-capture plant, which extracts CO2 from the air, thereby directly removing CO2 from the atmosphere.

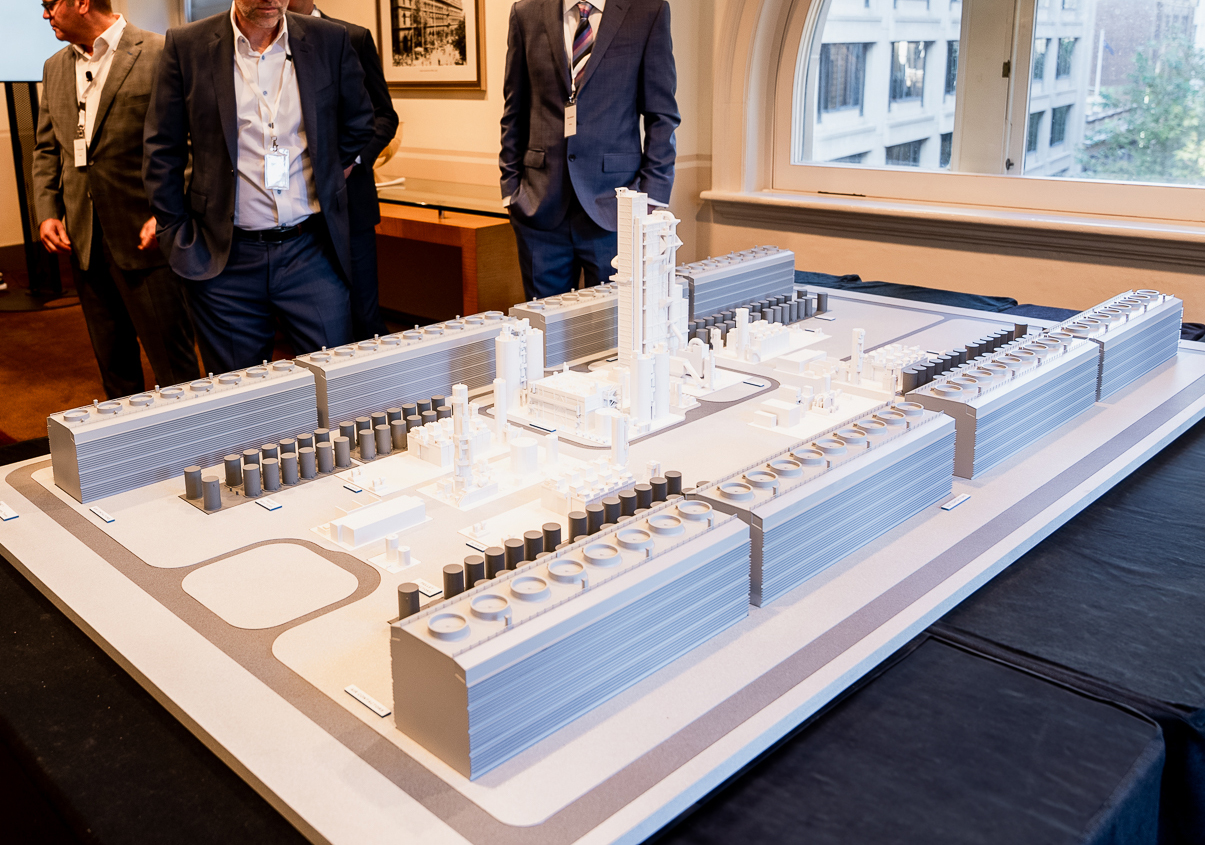

Recognising the need for a visually striking display, we approached Sydney-based Porter Models, renowned for its expertise in model building, to collaborate on constructing the custom table to showcase the printed architectural models. The collaboration aimed to provide a comprehensive solution by combining our expertise in 3D printing and Porter Models’ craftsmanship in model assembly and display.

Challenge:

The timing of this project was critical, with Investor Day fast approaching. The time constraint posed a significant challenge as the models needed to be printed and painted at our factory in Melbourne, and then assembled at Porter Models in Sydney, all within a tight five-day timeframe. Moreover, the complexity of the carbon-capture plant’s design required utmost precision and attention to detail to ensure the models accurately represented the intricacies of the facility.

Solution:

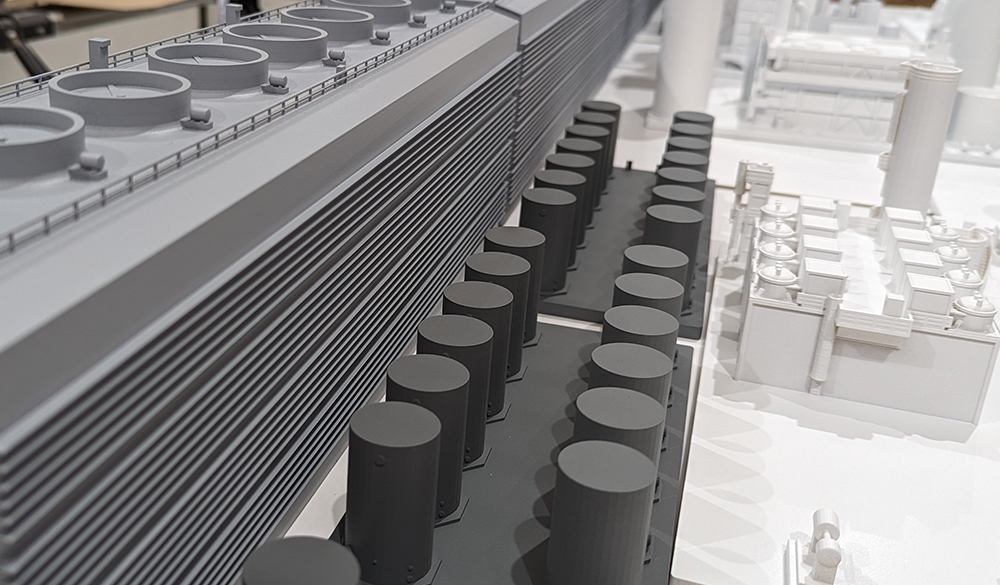

To meet the project requirements, we utilised our expertise in 3D printing, leveraging advanced printers and high-quality materials. To ensure perfect results, and to reduce the print time, we used three of our SLA printers simultaneously. The iPro 8000, Projet 7000 and ProX 800 printers are known for their precision and reliability in producing large intricate models. Complementing these printers, the materials used were Accura ClearVue, Accura 25 and Accura Xtreme.

Formero’s skilled technicians dedicated their efforts to post-processing the printed models, meticulously refining, smoothing, and painting the surfaces to achieve a professional finish.

By utilising the three printers and three materials, we were able to expedite the order and successfully produced highly accurate and visually impressive architectural models of the carbon-capture plant. The combination of advanced printing technology and carefully selected materials ensured that the models truly represented the intricacies and aesthetics of the plant’s design, contributing to the success of Worley’s Investor Day presentation.

Result:

Working closely with Porter Models and Worley, the architectural models were successfully completed within the tight five-day timeframe. Porter Models received highly accurate models that fit perfectly onto the custom table. The complete project was then delivered to Worley in time for their investor day.

This collaborative effort between Formero, Porter Models, and Worley exemplifies the benefits of using 3D printing technologies in rapidly producing intricate architectural models.

Ready to speak with us?

If you have questions please feel free to contact us.

Other Case Studies.

Project Flock’s Hybrid Manufacturing Approach

Through Formero’s Hybrid Manufacturing solution, Project Flock were able to bring their innovative Biomotion tail light to market.

Read MoreAtom Industries – Leaf Blower

See how Formero’s 3D Printing Technology helped Atom Industries, an an innovative leader in the development and manufacture of lawn and garden equipment, improve their leaf blower’s design and performance.

Read MoreEmirates Uses SLS 3D Printing For Supply Chain Efficiency

With a fleet of over 252 aircrafts, Emirates airlines saw cost saving opportunities through lighter weight parts, reduced inventory, and a more efficient supply chain using 3D printing technology.

Read More