Emirates Uses SLS 3D Printing For Supply Chain Efficiency

With a fleet of over 252 aircrafts, Emirates airlines saw cost saving opportunities through lighter weight parts, reduced inventory, and a more efficient supply chain using 3D printing technology.

Safety first: materials matter

Although Emirates was extremely interested in taking advantage of 3D printing for all the benefits additive technology offers, they laid out the material and certification requirements that needed to be met for final 3D printed parts to pass inspection and be incorporated in the aircraft cabin.

Using 3D Systems flame retardant 3D printing nylon material, Emirates were no longer bound by injection moulding design rules and able to optimise their designs to create fit-for-purpose parts with an optimised strength-to-weight ratio.

The nylon material also passes AITM smoke density and toxicity requirements and has a UL certification for consumer goods.

Designing fit-for-purpose parts: Video monitor project

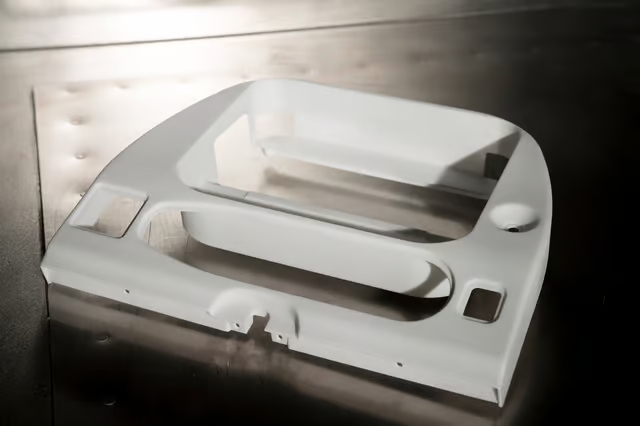

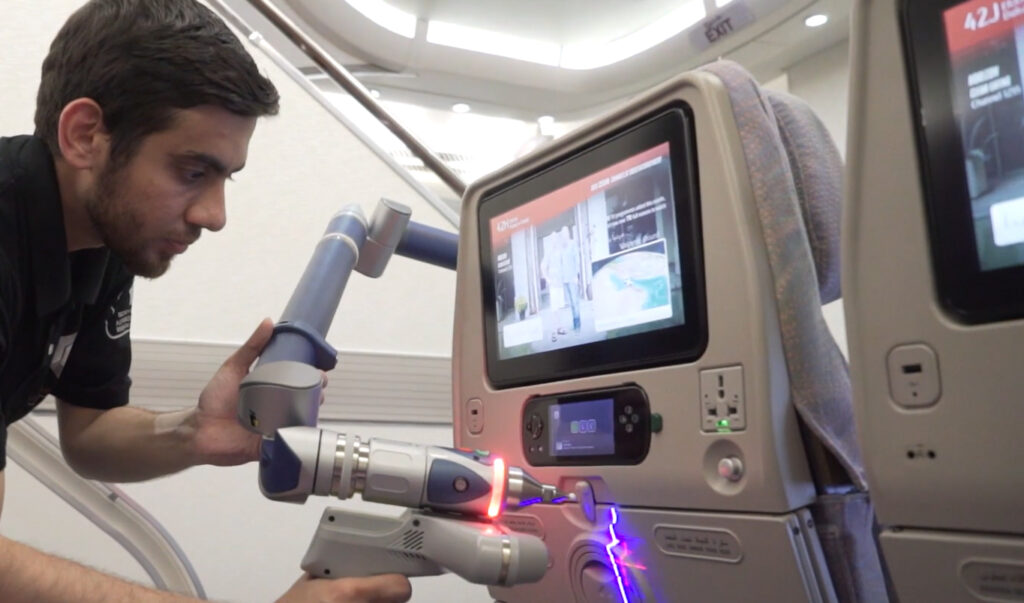

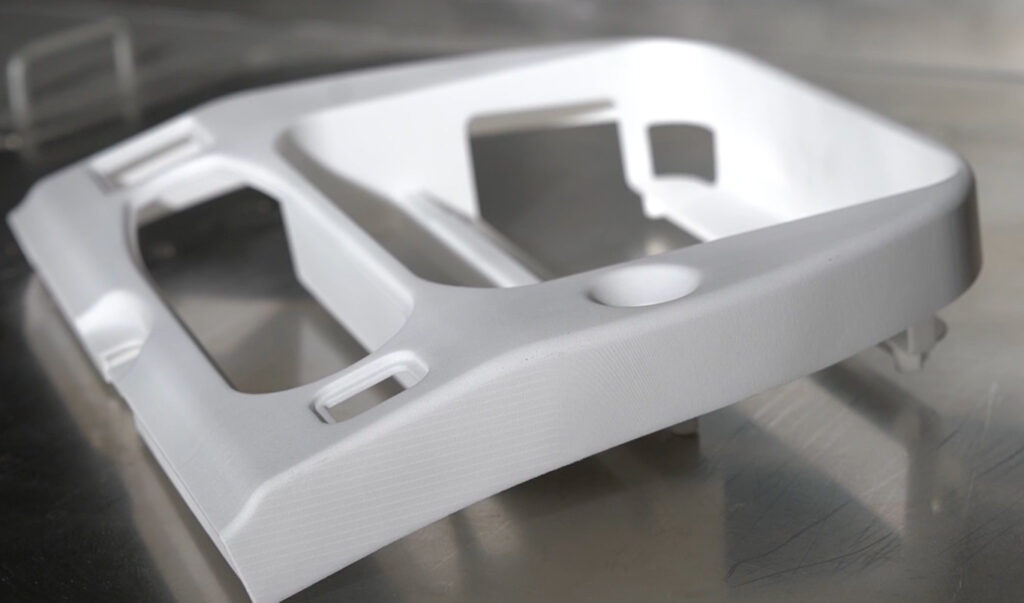

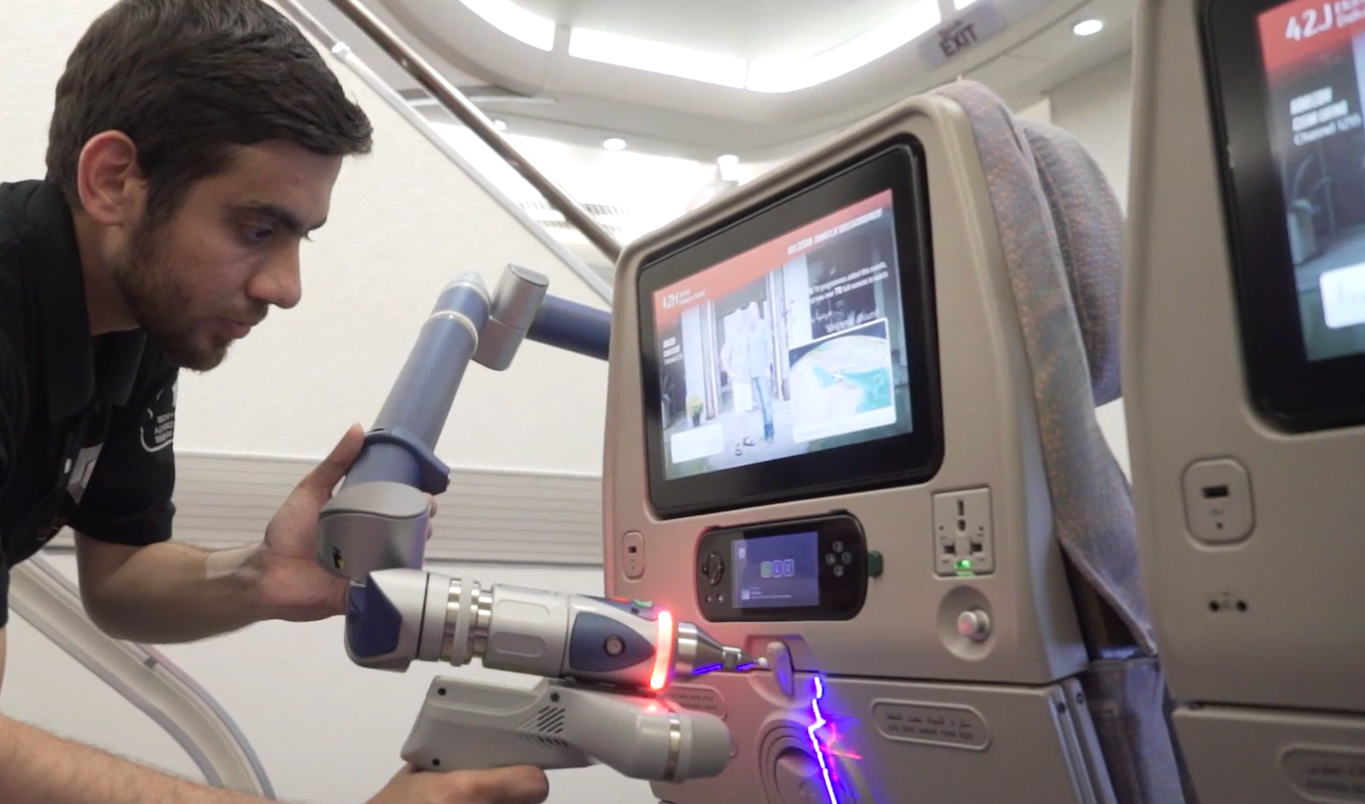

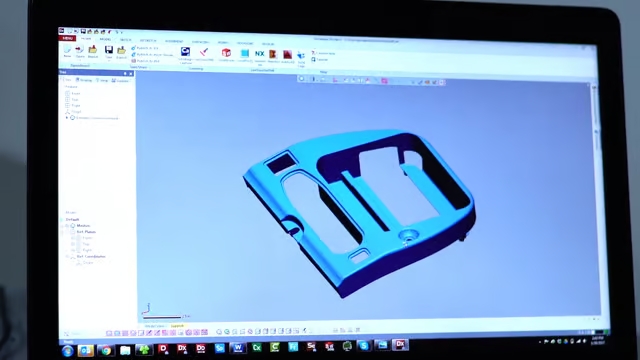

Emirates were keen to explore the 3D printing production process for a video monitor shroud. But without pre-existing CAD data, Emirates enlisted help from 3D scanning technology to collect point cloud data, and Geomagic Design X – reverse engineering software.

Because the final part would be 3D printed, the design was no longer constrained by the need to adhere to draft angles and consistent thicknesses. This enabled a number of design improvements over the original part.

Using SLS 3D printing technology, it offered Emirates lighter components, faster manufacturing, and the ability to produce multiple parts at the same time.

When reviewing the broader supply chain, the team at Emirates saw potential cost advantages now they could cut that supply chain into a software file that’s hosted in a virtual warehouse. In environments like the airline industry where maintaining large volumes of stock for every individual cabin component is part of standard operating procedure and cost, relocating warehouse aisles to file names is an incredible opportunity.

SLS 3D printing and On Demand Manufacturing

Using SLS 3D printing technology, the video monitor shrouds were 13% lighter than their conventionally manufactured counterparts. Geomagic Control X – 3D inspection and metrology software verified part accuracy by comparing the final printed geometry to the original digital file.

The new printed parts were then sent for manufacturing certification by UUDS, a European aviation engineering and certification office. They put the 3D printed parts through a broad range of structural, durability, flammability and chemical testing. Satisfied with the properties and performance of the DuraForm 3D Systems material, Emirates transitioned the new 3D printed components for onboard trials and full certification.

3D printing applications in the aerospace industry

The aerospace industry relies on innovation to grow and overcome challenges.

3D printing is one of the most disruptive manufacturing processes to have hit the engineering industry. It has the potential to change how we create plastic and metal structures and components across all industries, and is starting to make a difference in the aviation and aerospace industries.

3D printing technology has allowed greater supply chain flexibility and improve cost competitiveness, while leveraging on reduced material consumption and waste.

For full details visit the 3D Systems Case Study

Relevant Services.

Ready to speak with us?

If you have questions please feel free to contact us.

Other Case Studies.

3D Printing for Race Cars: Enhanced Cooling Efficiency

MMS needed to prevent overheating in their motors & inverters. The challenge was to create durable, heat-resistant parts that would manage thermal loads effectively.

Read MoreProject Flock’s Hybrid Manufacturing Approach

Through Formero’s Hybrid Manufacturing solution, Project Flock were able to bring their innovative Biomotion tail light to market.

Read MoreQuick Turnaround Architectural Models

Using SLA we 3D Printed Architectural Models in as little as 5 days for a carbon-capture plant, which extracts CO2 from the air, directly removing CO2 from the atmosphere.

Read More