Comprehensive Guide to Reaction Injection Moulding (RIM)

May 27, 2024

What is Reaction Injection Moulding (RIM)?

Reaction Injection Moulding (RIM) is a manufacturing process that utilises liquid polymers to create solid parts through a chemical reaction. This Guide to Reaction Injection Moulding looks into how this method is distinct from traditional injection moulding due to the use of thermosetting polymers, which are mixed and injected into a mould where they chemically react and cure, forming durable and lightweight components. RIM is especially useful for producing large, intricate parts with fine details and high-quality finishes.

How RIM Works

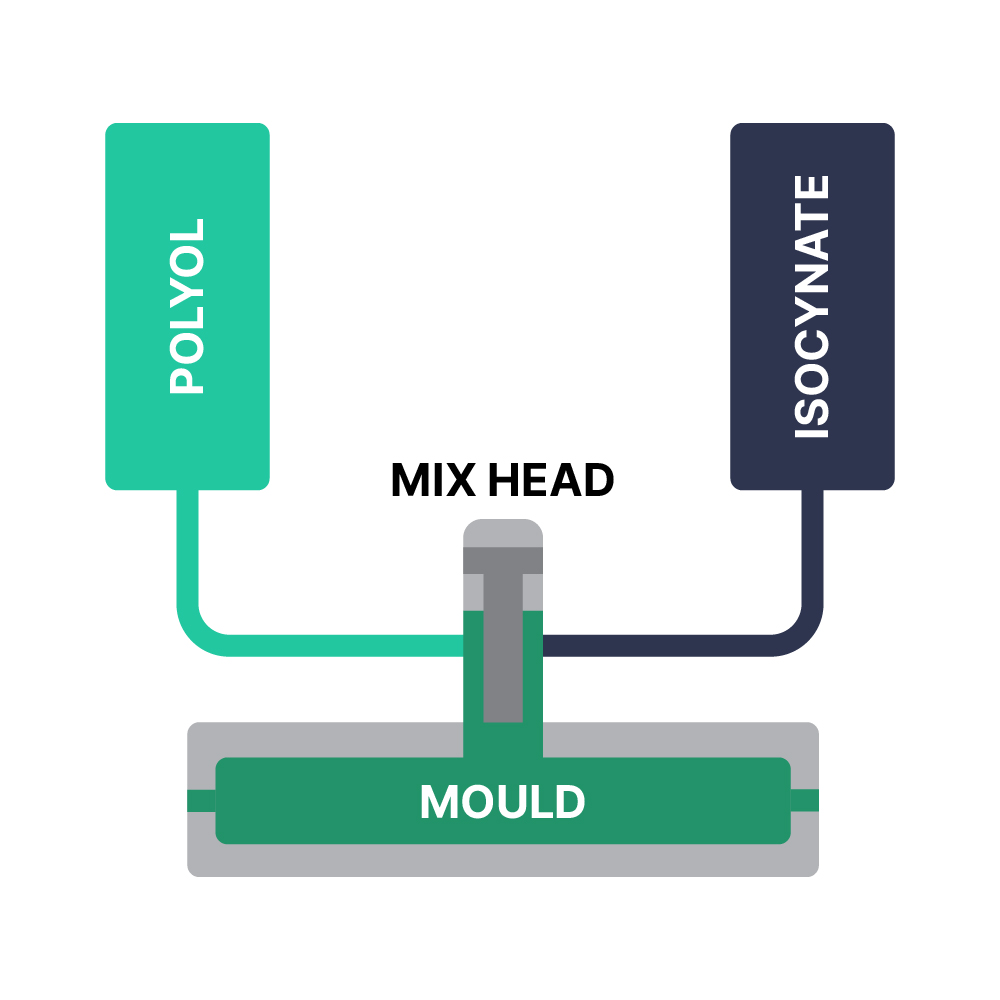

- Mixing: Two liquid components, typically isocyanate and polyol, are combined in a high-pressure impingement mixing head. The precise mixing ensures a consistent reaction and material properties.

- Injection: The mixture is injected into a pre-prepared mould at relatively low pressures compared to traditional injection moulding. This low-pressure injection helps to minimise the stress on the mould and the final part.

- Chemical Reaction and Curing: Inside the mould, the isocyanate and polyol react to form a polyurethane polymer. This chemical reaction generates heat, curing the polymer and solidifying the part.

- Demoulding: Once the material has fully cured, the mould is opened, and the finished part is removed. The part may then require post-processing such as trimming or painting.

RIM Benefits

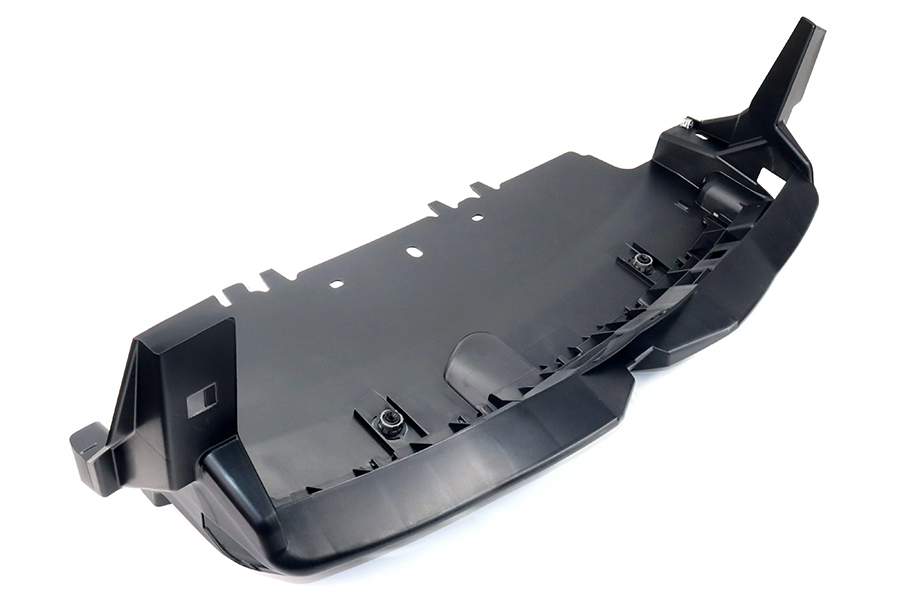

- Large Part Production: RIM is particularly effective for producing large parts, such as automotive bumpers and body panels, due to its ability to fill large moulds uniformly.

- Design Flexibility: The process supports intricate designs, allowing for varied wall thicknesses and complex geometries within the same part. This flexibility enables the creation of parts that are both lightweight and strong.

- Cost-Effective Tooling: The lower pressures used in RIM reduce wear on moulds, resulting in longer mould life and lower tooling costs. This makes RIM suitable for both low and medium-volume production runs.

- High-Quality Surface Finish: Parts produced through RIM often have excellent surface finishes, which can be painted or otherwise treated to meet specific aesthetic and functional requirements.

- Material Properties: RIM materials can be formulated to achieve a wide range of physical properties, including varying degrees of rigidity, flexibility, impact resistance, and thermal stability.

RIM Applications

- Automotive Industry: RIM is widely used for making automotive parts such as bumpers, fenders, and interior components due to its ability to produce lightweight yet durable parts that can be easily painted or textured.

- Medical Equipment: The precision and quality of RIM make it ideal for manufacturing medical device housings and enclosures, which require stringent standards for strength and hygiene.

- Consumer Goods: RIM is used to create various consumer products, including furniture components, casings for electronics, and recreational equipment, benefiting from the method’s versatility and cost-effectiveness.

How Does RIM Differ From Injection Moulding?

Reaction Injection Moulding (RIM) differs from traditional injection moulding in several key ways. The materials used in RIM are thermosetting polymers, which undergo a chemical reaction to cure and solidify, whereas traditional injection moulding typically uses thermoplastics that melt and then solidify upon cooling. RIM operates at much lower injection pressures, reducing stress on the mould and allowing for the production of larger and more complex parts. The curing process in RIM is driven by a chemical reaction that generates heat, unlike the cooling process in traditional injection moulding. Additionally, the lower pressures in RIM lead to less expensive tooling, making it more cost-effective for low to medium production volumes. RIM is also particularly suited for creating parts with intricate designs, varied wall thicknesses, and high-quality finishes that are challenging to achieve with traditional injection moulding.

Disadvantages of RIM

While Reaction Injection Moulding offers numerous benefits, it also has some drawbacks:

- Longer Cycle Times: The curing process in RIM is generally slower compared to the cooling process in traditional injection moulding, leading to longer cycle times for part production.

- Material Costs: The raw materials used in RIM, such as specific types of polyurethane, can be more expensive than those used in traditional injection moulding, potentially increasing overall production costs.

- Complex Chemical Handling: The chemicals involved in RIM, particularly isocyanates, require careful handling and safety measures due to their reactive and potentially hazardous nature.

- Limited Material Choices: Compared to traditional injection moulding, which offers a wide range of thermoplastic materials, RIM has a more limited selection of thermosetting polymers, which can constrain material options for specific applications.

- Post-Processing Requirements: Parts produced by RIM often require additional post-processing, such as trimming, painting, or coating, which can add time and cost to the manufacturing process.

Design Guidelines

- Material Selection: Choose polymers based on the required mechanical properties, such as flexibility, hardness, and thermal stability. Understanding the end-use environment is crucial for selecting the right materials.

- Wall Thickness: Maintaining a uniform wall thickness is essential to avoid defects such as warping or sink marks. Gradual transitions in thickness are preferable to abrupt changes.

- Draft Angles: Including appropriate draft angles (typically 1-3 degrees) in the design helps with the easy removal of the part from the mould, reducing the risk of damage during demoulding.

- Ribbing and Bosses: Incorporating ribs and bosses can enhance the structural integrity of the part without significantly increasing weight. These features should be designed to avoid creating stress concentrations.

- Tolerances: Account for the slight shrinkage and expansion of materials during the curing process. Setting realistic tolerances ensures that the final parts meet the required specifications.

Conclusion

Reaction Injection Moulding is a versatile and efficient process for manufacturing high-quality, durable, and lightweight parts across various industries. Its unique advantages in producing large, complex parts with excellent surface finishes make it an attractive option for many applications. However, it is important to consider the potential disadvantages, such as longer cycle times and material costs, when choosing RIM for your production needs. For more information and to explore how RIM can benefit your production needs, visit our Reaction Injection Moulding page.

Author

Craig Alexander

Craig is a seasoned marketing professional with over 13 years of diverse experience in industries ranging from Asphalt Testing Technology to Environmental Sciences. His extensive background in B2B marketing, coupled with a deep understanding of complex technical fields like Power Tools, Solar & Battery Systems, and Emergency Lighting, uniquely positions him to bridge the gap between advanced manufacturing technologies and market needs. Craig leverages his comprehensive marketing skills to translate intricate manufacturing processes and innovations into clear, compelling narratives, helping businesses of all sizes succeed in both local and international markets.