Small Yet Critical: 3D Printed End Caps by Formero

November 8, 2024

In 2024 Formero was proud to sponsor Monash Motorsport (MMS), a student-run race team. The team is comprised of Monash University students from a range of faculties, including engineering, commerce, science, design and law; that work collaboratively in technical, business and management aspects. The culmination of this is the team’s consistent success in FSAE Australasia and in European Formula Student competitions.

The following post was written by the students at Monash Motorsport as part of our ongoing relationship. We would like to take this opportunity to congratulate the 2024 MMS Team on their successes and look forward to working with them in 2025.

Small Yet Critical: 3D Printed End Caps by Formero

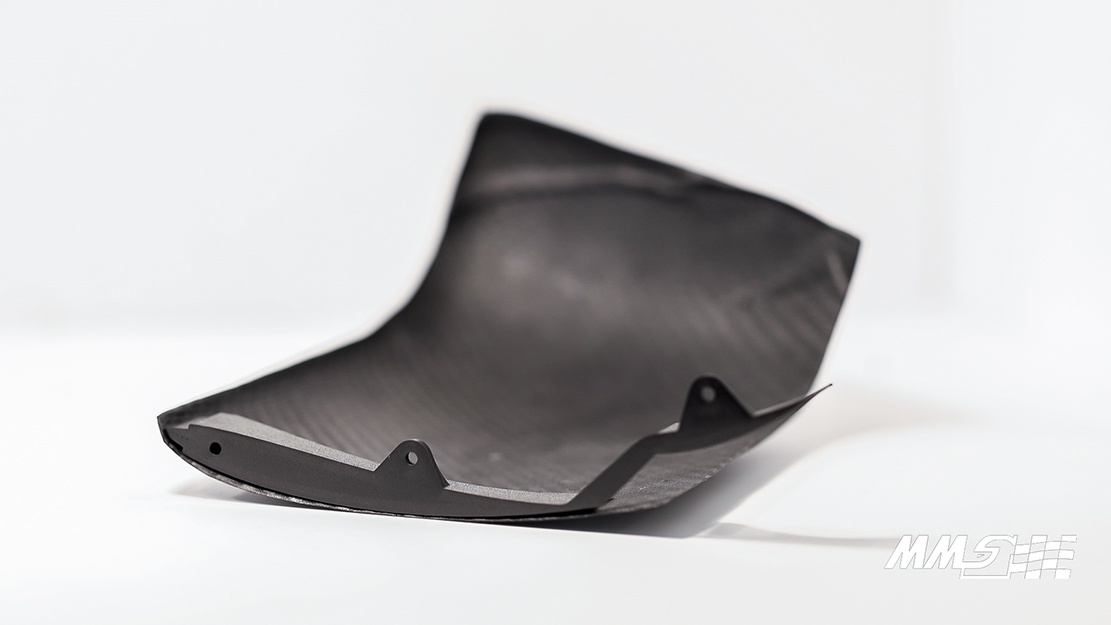

Formero has been a partner of Monash Motorsport for many years, and are renowned for their high quality 3D printing services. Our aerodynamic wing profiles require end caps for assembly of the carbon fiber skins and to transfer loading to the mounting structure. They have to be lightweight, yet stiff enough to pass deflection rules. As such, end caps are highly important components of our car that enable our aerodynamic package to be suitably attached to the vehicle. Particularly for smaller wing elements, like the front wing flaps, end caps can be difficult to manufacture reliably by hand. Therefore, our team has partnered with Formero to manufacture these very small, yet critical parts for our car.

Monash Motorsport has worked with Formero to create our end caps through a 3D Printing process called Fused Filament Fabrication, more commonly known as FDM. It is a process in which filament is extruded through a moving, heated nozzle, constructing the project layer by layer, and it is known for its uses as an economical and multifaceted method of 3D printing. The material we chose was Onyx™ – the flagship base material from MarkForged – a high-performance micro carbon fibre filled nylon, which has a 40 MPa tensile stress at yield and 37 MPa at break, which forms the ideal properties for our use case.

Previously, we have utilised Selective Laser Sintering (SLS), where the project is created using a laser to sinter powder particles, and binding the layers together. However, we ultimately chose to use Onyx™ this year due to its high performance and versatility.

Formero has been consistently reliable and timely for all projects we have collaborated on, such as cooling jackets for the motors. The team knew that for our European Campaign, we would be on a tight timeline – all these parts had to be ordered, manufactured, delivered and tested before our shipping container departed from Melbourne in April, across the world to Germany. We had two aerodynamic packages to allow for sufficient spares should they be required, totalling to a large quantity of end caps required. Within a few weeks, we had received our end caps in pristine quality, on time and meeting our strict requirements.

James Hazon, our Aerodynamics Principal Engineer, who was involved in the design and completion of these parts, has shared:

“With manufacturing two aero packages before shipping M24 came increased time constraints. Formero was able to accommodate for this providing a very fast turnaround, even for the large quantity of parts asked of them. All were delivered to high quality allowing us to form our aerofoils as accurately as possible. I would like to thank Formero on behalf of Monash Motorsport and all the projects we have brought to them over the years.”

The end caps we received from Formero were outstanding in all respects – quality, timing, precision and service. We would like to thank Formero for their continued support, which has allowed M24 to travel and compete in Europe successfully.

Author

Craig Alexander

Craig is a seasoned marketing professional with over 13 years of diverse experience in industries ranging from Asphalt Testing Technology to Environmental Sciences. His extensive background in B2B marketing, coupled with a deep understanding of complex technical fields like Power Tools, Solar & Battery Systems, and Emergency Lighting, uniquely positions him to bridge the gap between advanced manufacturing technologies and market needs. Craig leverages his comprehensive marketing skills to translate intricate manufacturing processes and innovations into clear, compelling narratives, helping businesses of all sizes succeed in both local and international markets.