3D Printing Services

Our 3D Printing Service

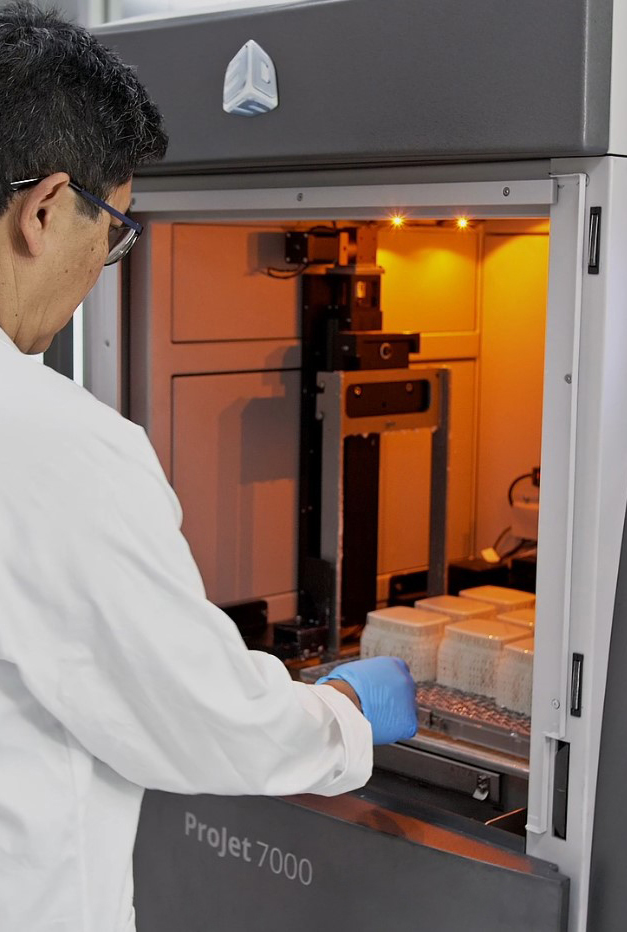

As Australia’s largest and most advanced 3D Printing Service Bureau, we are committed to bringing your ideas to life with speed and efficiency. When you choose Formero, your projects will take shape in our state-of-the-art printing lab located in Melbourne, Victoria.

At Formero, we feature the most comprehensive in-house capability with 12 distinct 3D printers spanning 6 advanced technologies. This diversity allows us to cater to a wide range of projects, whether you’re in aerospace, healthcare, or any other industry. With over 20 materials at our disposal, we can transform your concepts into reality using the ideal material for your requirements.

From rapid prototyping to additive manufacturing processes, our expertise in 3D printing is unparalleled, spanning limitless commercial and industrial applications. Our team’s dedication to precision and craftsmanship ensures that your creations are handled with the utmost care.

Benefits of 3D Printing with Formero.

Customisation

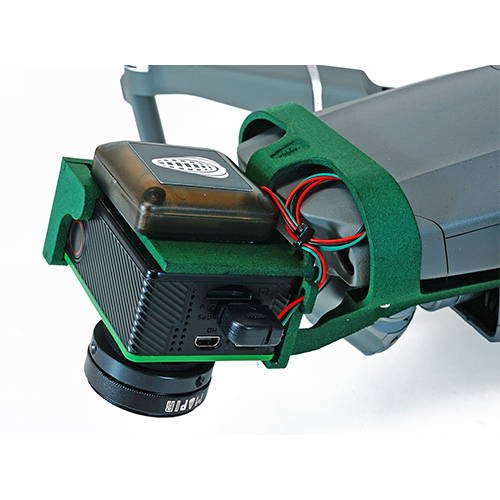

Tailor your products to specific requirements, offering personalised solutions for your projects.

Cost-Effective

Reduce production costs by eliminating the need for complex tooling and moulds, especially for low-volume or custom designs.

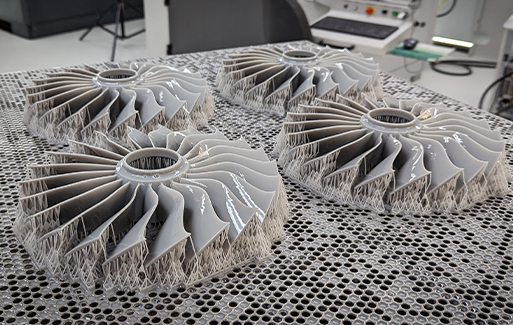

Complex Geometries

Create intricate and complex designs that traditional manufacturing methods simply can’t replicate.

Speed and Efficiency

Shorten your development cycle with rapid prototyping and post-processing, enabling faster iterations and reduced time-to-market.

Available 3D Printing Technologies.

3D Printing vs Additive Manufacturing.

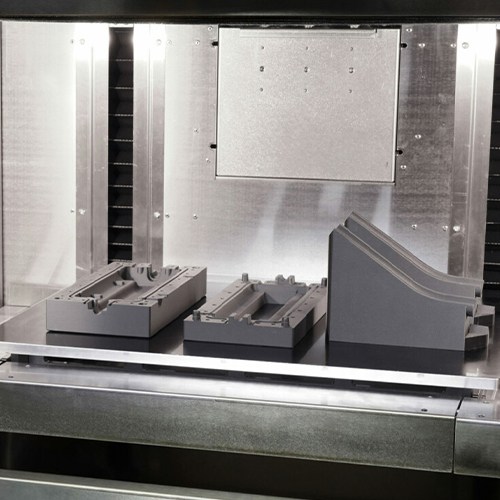

The distinction between 3D Printing and Additive Manufacturing Processes is primarily defined by the number of parts involved. The term 3D Printing is more often used when printing in smaller batches, typically around 1-20 prototypes, offering a precise and swift solution.

Additive Manufacturing Processes, on the other hand, step in for larger production needs, ranging from 100-200 parts. The Additive Manufacturing Process is the opposite of subtractive manufacturing – which works by cutting out part of the material to create the final product. Additive Manufacturing is often associated with selective laser sintering, multi-jet fusion and digital light processing technologies.

These manufacturing methods showcase its capacity to meet substantial manufacturing requirements.

3D Printing Materials.

Our range of 3D printing materials encompasses a wide variety of properties and characteristics, allowing us to create parts that meet your exact specifications. For more information on our full range of materials, you can view our materials page or visit each service individually. Some popular materials we use for 3D Printing include:

- ABS

- Nylon 11 & Nylon 12

- Glass Filled Polyamide (Nylon)

- Fibre-reinforced Composites (Nylon)

- Flame Retardant Materials

- Nylon Copolymers

- Rubber

- Continuous Fiber Reinforced Nylon

- HDPE-like Nylon blend

- PEI Thermoplastic

- Polypropylene

- Photopolymer Resin

- Polycarbonate-like Clear Resin

Benefits of 3D Printing.

Unlike most conventional manufacturing methods, 3D Printing processes present numerous benefits that make it the preferred choice for many industries. These include:

- Greater design flexibility: While many traditional manufacturing processes are limited by complexity and geometrical constraints, 3D Printing allows for more intricate designs to be created with ease.

- Faster production: 3D Printing can produce parts in a fraction of the time compared to traditional manufacturing methods, thanks to its layer-by-layer fabrication process.

- Reduced waste: With 3D Printing, only the necessary material is used, significantly reducing waste compared to subtractive manufacturing methods.

- Lighter and stronger parts: The layered construction of parts in 3D Printing results in stronger and lighter products, making it ideal for industries such as aerospace and automotive.

- Customisation: 3D Printing allows for the creation of highly customised products that cater to specific requirements, making it a popular choice for industries such as medical and orthotics.

- Cost-effective: With no need for complex tooling and moulds, 3D Printing can be a more cost-effective option for low-volume or custom designs.

Ready to speak with us?

If you have questions please feel free to contact us.