5 Reasons to Consider Manufacturing Custom CNC Parts?

November 23, 2023

If you’re creating a product that requires a unique and complex part, then you’ve probably considered a few methods for manufacturing it.

While there are many options available, CNC machining stands out as a popular choice for creating parts with precision, accuracy and speed.

In this blog post, we’ll explore five reasons why you should consider manufacturing custom CNC parts for your next project. But first, let’s briefly describe what CNC machining is and how it works.

What Is CNC Machining?

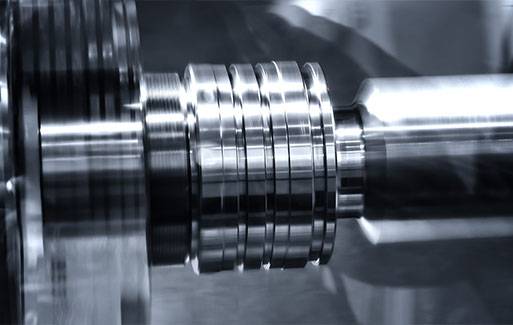

CNC (Computer Numerical Control) machining is a manufacturing process that involves the use of computers to control machine tools. It’s a subtractive manufacturing method, meaning that it removes material from a larger piece to create the desired shape and size.

The CNC manufacturing process involves using computer-aided design (CAD) software to create a 3D model of the part you want to manufacture. The software then translates this model into instructions that control the movement of the CNC machines, which use cutting tools such lasers or other cutting machines, to remove material from a solid block until the desired shape is achieved.

Now that we have a basic understanding of CNC machining let’s dive into the five reasons why it’s an excellent option for custom part manufacturing.

Benefits of Custom CNC Machining

CNC machining offers a host of benefits, which makes it an attractive option for creating custom parts. Let’s look at some of these benefits in detail:

1) Full-strength parts

With CNC Machining, you can create parts from a range of materials, including metals, plastics, and polymers. This process allows you to achieve full-strength parts with excellent surface finishes that are ready for use right out of the machine.

Achieving full-strength parts is especially essential when you’re creating parts for real-life use cases or high-stress applications. CNC Machining ensures that your custom parts can withstand the required load and provide long-term reliability.

2) Wide range of materials available (includes polymers and metals)

As mentioned earlier, CNC machining offers a wide range of material options for creating custom parts. This flexibility means that you can choose the best material for your specific application without compromising on strength or quality.

For example, if you need a part with high heat resistance, CNC machining can help create it from materials like titanium or stainless steel. On the other hand, if your part requires flexibility and impact resistance, you can opt for plastics that fit these characteristics.

3) Scalable Production Volumes

CNC machining is a versatile process that can offer some flexibility with production volumes. This scalability makes it perfect for businesses of all sizes who may want to start with smaller volumes and then slowly scale up production for their custom CNC parts.

As the process is automated, it also allows for consistent quality and precision. This means that you can produce your parts with the same level of accuracy consistently. With this level of scalability, you can easily test your prototypes and make necessary changes before ramping up production.

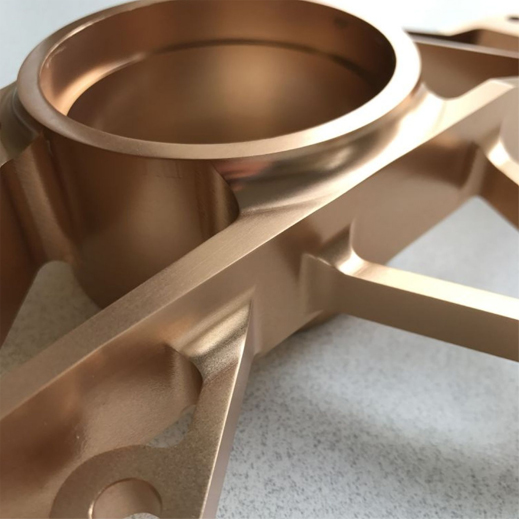

4) Surface Finish Varieties

Another advantage of CNC machining is that it offers a variety of surface finishes. The sharp cutting tools used in the process can achieve smooth, polished surfaces with complex details and intricate patterns.

Some of the finishes that CNC machining offers include:

- Painting: This finish is great for adding colour to your parts and giving them a unique look.

- Anodising: A surface treatment that increases the thickness of the natural oxide layer on metal parts, making them more resistant to corrosion and wear.

- Sanding Blasting/Glass Bead Blasting: Mainly used for visual purposes and comes in several different grits which indicate the size of the bombarding pellets.

- EMI: An electroless nickel coating that provides excellent conductivity and EMI shielding properties.

- Hand Polishing: This technique allows for precise, manual smoothing and polishing of parts to achieve a glossy finish.

This versatility allows you to create custom parts that not only function but also look aesthetically pleasing. This feature is especially useful for creating consumer products or items where appearance and branding are crucial. Contact us today to discover our full range of finishes available.

5) Complex Designs/Complexity

Another reason to consider manufacturing custom parts using CNC machining is its ability to achieve complex designs and geometries accurately. This process allows for intricate details and shapes that may be required for your part’s functionality.

Furthermore, CNC machining also enables the production of custom parts with tight tolerances. This accuracy is essential for creating parts that need to fit precisely with other components or parts.

Examples of CNC Machining Projects

- Presentation Models (medical and packaging): With CNC machining, you can create customisable, high-quality presentation models for medical and packaging purposes with intricate details. For example, you can create intricate models of organs or packaging prototypes with smooth, polished surfaces that accurately represent a realistic product or the final product.

- Automotive parts and accessories: CNC machining is commonly used in the automotive industry for creating custom parts and accessories like gears, engine components, and even entire car body frames.

- Medical Devices: CNC Machining is ideal for producing custom medical devices that require complex designs and accurate tolerances. This process can help create medical implants, surgical tools, prosthetics, and more.

- Security system components: CNC machining is also used to manufacture security system components like locks, safes, and even components of surveillance equipment. Its accuracy and versatility make it an excellent option for creating intricate parts for these systems.

- Electronic Components and Housings: CNC machining is also used to manufacture custom electronic components and housings for a variety of devices, such as smartphones, computers, and other gadgets. Its precision can help achieve the tight tolerances required for these parts, ensuring proper functionality.

- Marine parts and accessories: CNC machining is also used in the marine industry to create custom parts for boats, yachts, and other watercraft. With its ability to work with a variety of materials, it is suitable for creating both structural and decorative components.

How Formero Can Help You

If you are considering manufacturing custom CNC parts, Formero can help bring your ideas to life. We offer a range of services, including CNC machining, to help our clients create high-quality custom parts that meet their specific requirements.

Our CNC services come with several materials and finishes so that you have a wide range of options to choose from. If you need help selecting the best material or finish for your project, feel free to reach out to us and will be glad to discuss the best option for your needs.

Summary

CNC machining offers many benefits for manufacturing custom parts. It provides flexibility in material options, scalability in production volumes, a variety of surface finishes, the ability to achieve complex designs and tight tolerances, and is suitable for a wide range of industries.

If you have a project that requires custom parts, consider using CNC machining to achieve the best results. So don’t hesitate, contact us today and get started on creating your perfect custom CNC part.

Author

Craig Alexander

Craig is a seasoned marketing professional with over 13 years of diverse experience in industries ranging from Asphalt Testing Technology to Environmental Sciences. His extensive background in B2B marketing, coupled with a deep understanding of complex technical fields like Power Tools, Solar & Battery Systems, and Emergency Lighting, uniquely positions him to bridge the gap between advanced manufacturing technologies and market needs. Craig leverages his comprehensive marketing skills to translate intricate manufacturing processes and innovations into clear, compelling narratives, helping businesses of all sizes succeed in both local and international markets.