Post-Processing Services

3D Printing Post-Processing

At Formero, we understand that post-processing is a critical step in achieving the best possible quality for your 3D printed parts. Our comprehensive range of post-processing services is designed to refine, enhance, and perfect your parts to meet your exact specifications and standards.

Surface Finishing

Surface finishing involves enhancing the surface quality of parts, making them smoother and more aesthetically pleasing. This process can significantly improve the tactile and visual appeal of your products.

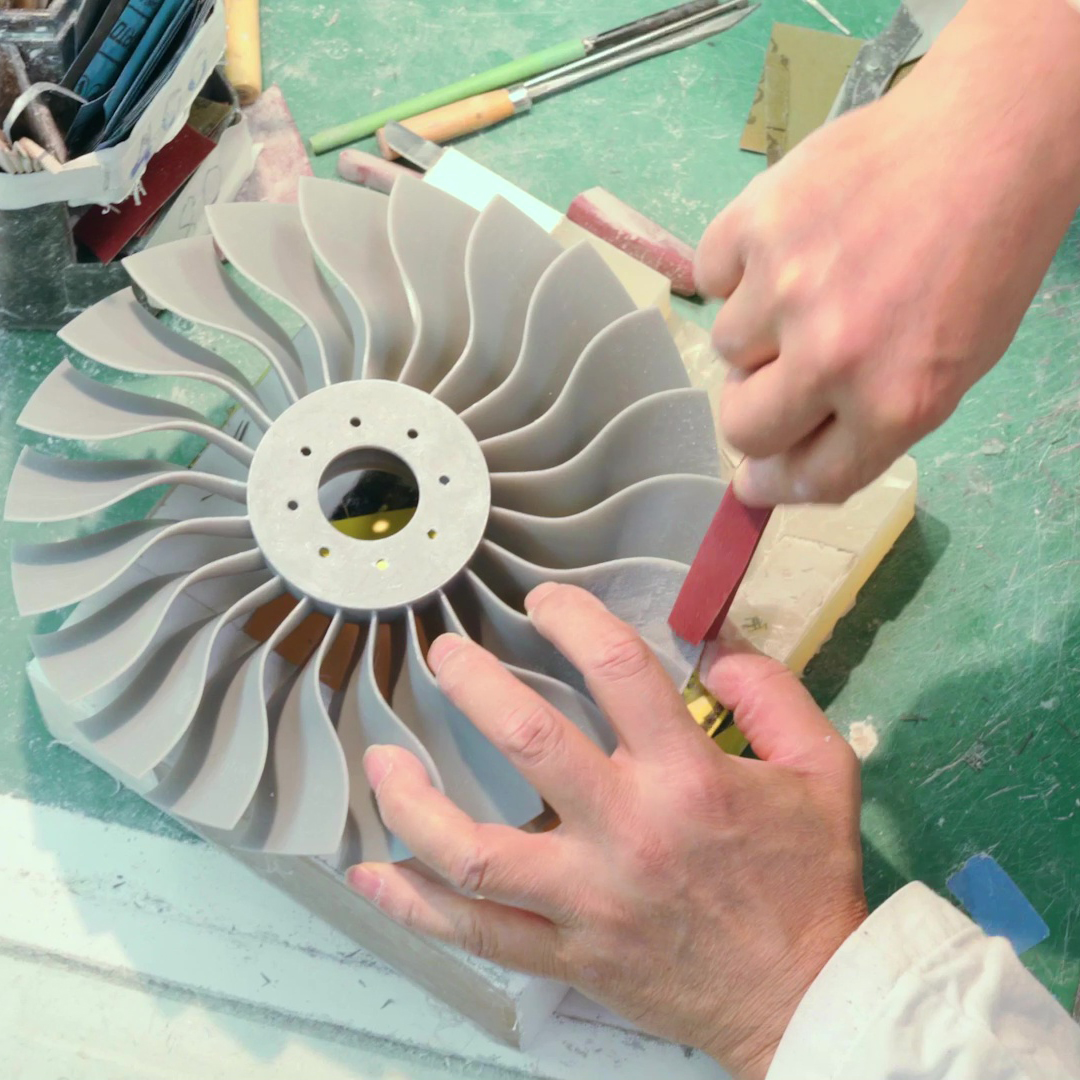

- Sanding: Sanding involves manually or automatically abrading the surface to remove rough spots, layer lines, and minor imperfections. This technique can be tailored to achieve various levels of smoothness, from coarse to fine finishes.

- Bead Blasting: Bead blasting uses fine beads propelled at high speed to clean and polish the surface of a part. This method is excellent for creating a uniform matte finish and can remove surface contaminants without damaging the part.

- Tumbling: Tumbling involves placing parts in a barrel with abrasive media that vibrates or rotates. This process smooths and polishes the surfaces, making it ideal for bulk finishing small to medium-sized parts efficiently.

SLA Finishing Grades

Formero offers various SLA (Stereolithography) finishing grades to meet your specific project requirements. Our finishing options ensure that your parts achieve the desired level of smoothness and clarity.

- Standard Finish: Supports are removed, affected surfaces are lightly sanded with 180-240 grit sandpaper and bead blasted to produce an even finish.

- Engineering Finish: Supports are removed along with external layer lines. Affected surfaces are sanded down using 400 grit sandpaper and bead blasted.

- Premium Finish: Supports are removed along with internal and external layer lines. Affected surfaces are sanded down using 400 grit sandpaper and bead blasted.

Painting, Dyeing & Coating

Painting and coating add colour, protection, and additional properties to your parts. This process not only improves the appearance but also enhances durability and resistance to environmental factors.

- Spray Painting: Spray painting involves applying paint through a fine spray, achieving an even coat over the entire surface. It is versatile and can be used for various colours and finishes, from glossy to matte. We are able to match any Pantone colour.

- Dyeing: Dyeing imparts colour to your parts by immersing them in a dye solution, providing uniform coloration throughout the material. We offer a variety of colours depending on part substrate. For MJF (Multi Jet Fusion) parts, we provide black dyeing as a standard service at no additional cost.

- Z-Bonding: Z-Bonding involves applying a bonding agent to CJP printed parts to improve their structural integrity and surface finish. This technique enhances the strength and durability of the printed parts. On request we can also apply this to SLS and MJF printed parts to improve water tightness and waterproofing at an additional cost.

- Clear Lacquer: Clear lacquer coating provides a glossy finish, improved transparency on clear SLA parts and additional protection to the surface. This coating enhances the aesthetic appeal and longevity of the parts by protecting against scratches and environmental factors.

Textures

Formero offers various texture options to enhance the aesthetic appeal and functionality of your 3D printed parts. Whether you require a subtle texture for improved grip or a more pronounced texture for added visual interest, we can customise the surface finish to meet your specific design requirements.

Threads & Inserts

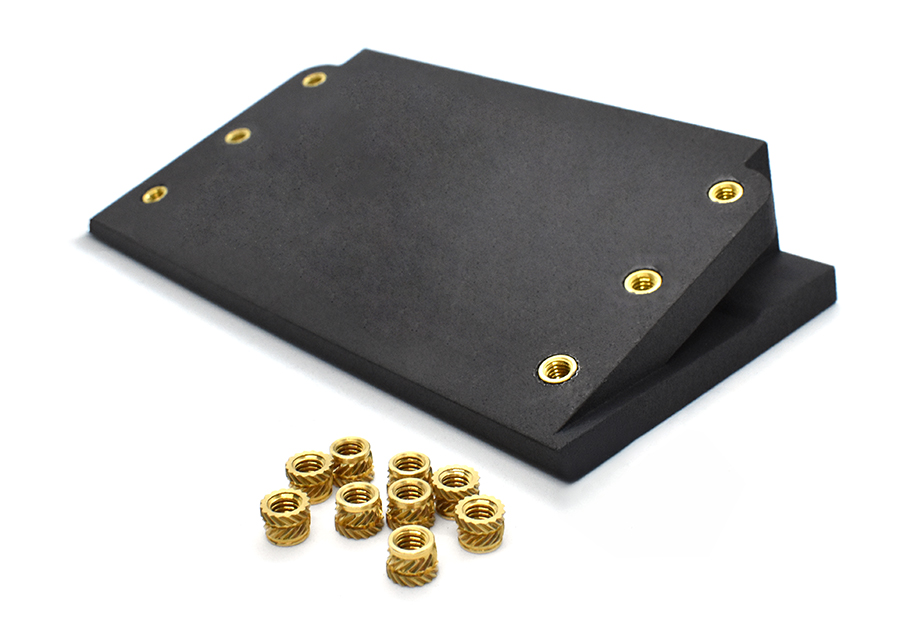

Formero offers direct tapping and threading for your printed parts, as well as the installation of inserts for large production runs. We accommodate most standard metric and imperial thread types, as well as commonly used heat set, press-fit, and tapping inserts.

Assembly and Testing

Assembly and testing ensure that your parts are not only individually perfected but also work seamlessly as part of a larger system. This service helps ensure functionality and reliability of complex assemblies.

- Manual Assembly: Our skilled technicians are able to assemble parts by hand, ensuring precise and careful assembly of components. This method allows for flexibility and detailed attention to complex parts and assemblies. This service can also include the glueing of two or more parts.

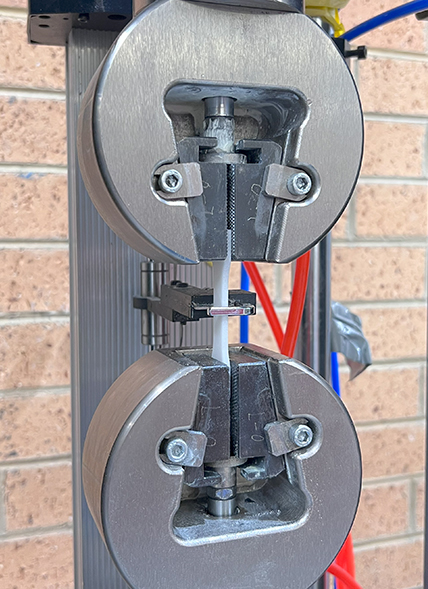

- Quality Testing: Rigorous testing procedures are conducted to ensure that parts meet specified requirements. Additionally, we offer First Article Inspection (FAI), which involves a detailed examination and testing of the first part produced from a new manufacturing process to verify that it meets all specifications and quality requirements.

Custom Post-Processing Services

If your project requires post-processing services beyond those listed above, please contact us. Our team is always ready to discuss custom solutions tailored to your specific needs. We are committed to finding the best methods to achieve your desired results.

Why Choose Formero?

At Formero, we pride ourselves on delivering exceptional quality and service in every project. Our team of experts is dedicated to providing top-notch post-processing services that meet your unique needs.

- Experience and Expertise: With years of experience in the industry, our team has the knowledge and skills to handle a wide range of post-processing requirements.

- Quality Assurance: We adhere to stringent quality control measures to ensure that every part meets the highest standards of quality and precision.

- Customer Service: Our commitment to customer satisfaction means we work closely with you to understand your needs and provide personalised solutions.

Ready to speak with us?

If you have questions please feel free to contact us.

Related Services.

Frequently Asked Questions (FAQ)

Post-processing involves refining and finishing 3D printed parts to improve their appearance, functionality, and performance. It is essential for achieving the final quality and precision required for various applications.

Our team can help you determine the best post-processing services based on your project’s requirements and desired outcomes. Contact us for a consultation.

Each material has specific post-processing techniques suited to its properties. We currently offer 21 different polymers through our 3D Printing Services.

The duration of post-processing depends on the complexity and type of service required. Most post-processing services add 1-2 business days to our standard lead time, but more intricate processes may take longer. We provide detailed timelines for each project upon consultation.

Yes, Formero is equipped to manage both small and large production orders. We utilise advanced technologies and efficient workflows to ensure timely delivery without compromising quality, regardless of the order size.

We have rigorous quality control measures to ensure every part meets the highest standards. This includes detailed inspections, precise measurements, and performance testing. Our quality assurance team ensures that all parts are thoroughly checked before delivery to our clients. We are certified under ISO 9001.