The Power of 3D Printed Prototypes in Modern Manufacturing

August 13, 2024

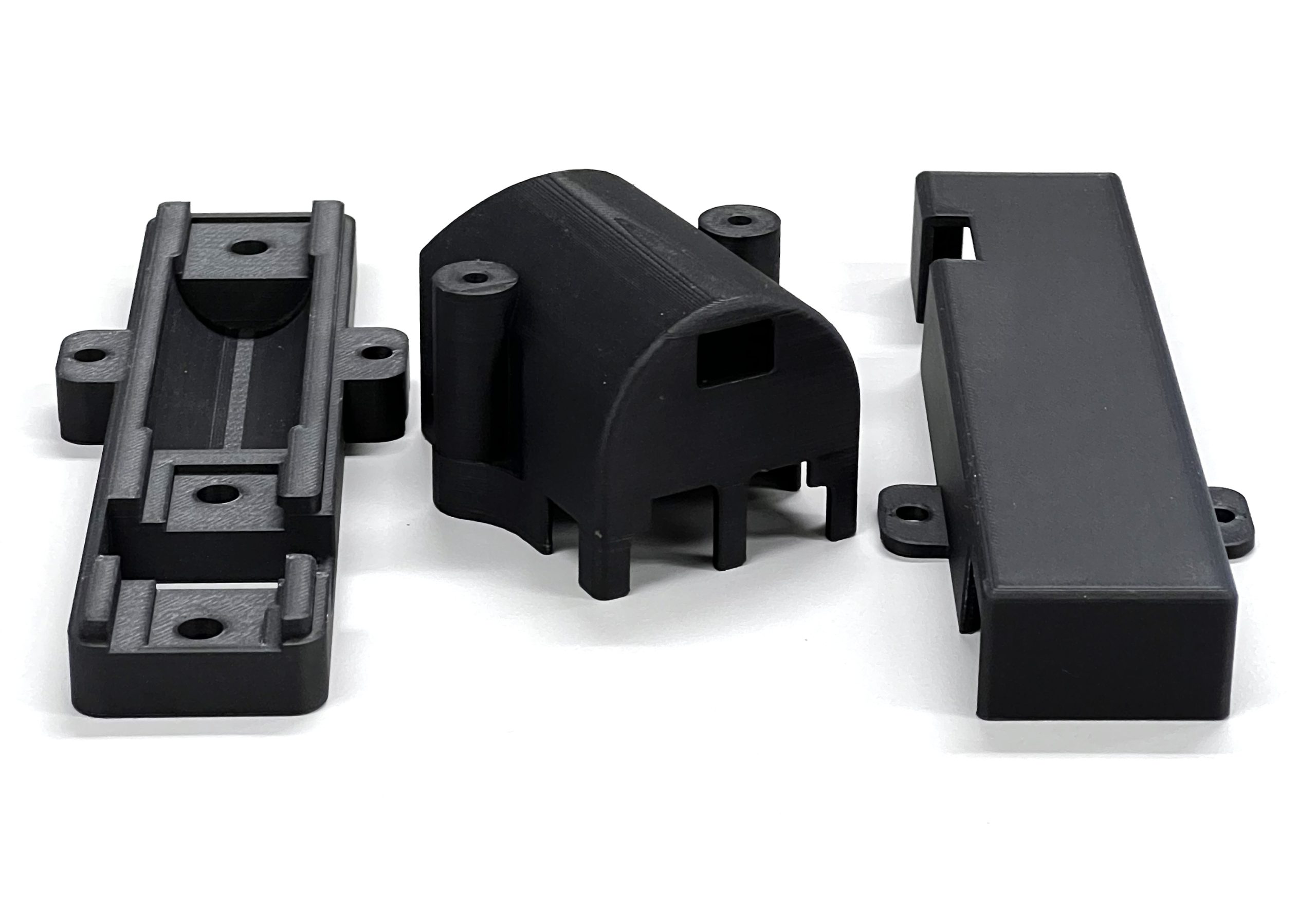

3D Printed Prototypes play a vital role in manufacturing, giving us a hands-on way to check a design’s functionality and look before going all out with production. It’s key for spotting design issues, evaluating user experience, and tweaking products to hit the right technical specs and meet consumer expectations. In our fast-paced market, 3D Printed Prototypes speed up design iterations and provide instant feedback, helping ensure products meet high standards and get to market quickly.

What is 3D Printed Prototyping?

3D Printed Prototyping is a transformative approach in manufacturing that enables the rapid creation of physical parts, models, or assemblies directly from 3D Computer-Aided Design (CAD) files. This innovative process primarily relies on additive manufacturing, commonly known as 3D printing. It excels at quickly converting digital designs into tangible prototypes, ranging from high-fidelity versions that closely resemble the final product to low-fidelity ones used for early concept validation.

The versatility of 3D Printed Prototyping includes various additive manufacturing techniques, with layered additive manufacturing being the most prevalent. However, other methods like high-speed machining, casting, moulding, and extruding also play a role in prototyping. This adaptability ensures that 3D Printed Prototyping can meet a wide range of design and material requirements, making it a powerful tool in modern product development.

Advantages of 3D Printed Prototypes in Product Development

- Faster Product Development: 3D Printed Prototypes speed up iteration and development cycles compared to traditional methods, cutting down time-to-market. This quick turnaround is crucial in today’s fast-paced market, where moving swiftly from concept to product can give a company a competitive edge.

- Cost Savings: By catching design flaws and functional issues early on, prototyping helps avoid expensive revisions later in the production process.

- Boosted Creativity: 3D Printed Prototypes promote experimentation and innovation by providing rapid feedback on design ideas, encouraging a more iterative and creative approach to product development.

- Real-Time Feedback: Testing prototypes with real users allows for immediate input, helping designers make informed decisions and adjustments based on user preferences and needs.

- Customisation and Personalisation: 3D Printed Prototypes make it possible to create custom and personalised products tailored to specific user requirements, enhancing customer satisfaction and loyalty.

- Risk Reduction: Early testing and validation of concepts through prototyping minimise the risk of product failure and ensure that final products meet customer expectations and market demands.

Low-Fidelity vs. High-Fidelity Prototypes: Choosing the Right Approach

- Low-Fidelity Prototypes: These are the initial, simple representations of a concept, often quickly produced. They’re used mainly for testing broader ideas, like paper sketches or cardboard mock-ups. The goal is to validate the overall concept of a product, allowing for rapid iteration and early user feedback during the earliest design stages.

- High-Fidelity Prototypes: These prototypes closely mimic the final product’s functionality, appearance, and user interface. They are more refined and provide a realistic user experience, making them ideal for detailed testing and presentations to stakeholders. High-fidelity prototypes are typically used in the later stages of product development when detailed feedback on the product’s functionality and user interface is crucial.

Selecting the Optimal Prototyping Technology

When choosing the right prototyping technology, several key factors must be considered to ensure a successful outcome:

- Cost: Assess the initial investment, operational costs, and material expenses to ensure they fit within your budget.

- Material Compatibility: Check if the technology supports the required materials, considering factors like strength, durability, and flexibility.

- Fidelity Requirements: Determine the level of detail and accuracy needed for your prototype and ensure the chosen technology can meet these requirements.

- Application Suitability: Identify the specific needs of the prototype, such as functional testing, visual representation, or end-use production, and select the technology that best suits these needs.

- Lead Time: Evaluate the production speed, setup time, and material lead times to ensure the technology can meet your project deadlines.

- Complexity of Geometry: Consider the prototype’s geometric complexity, including intricate features and internal structures, and choose a technology that can accurately reproduce these elements.

- Scalability: Ensure the technology can handle increased production volumes in the future without compromising quality or efficiency.

Conclusion

3D Printed Prototypes in Modern Manufacturing is changing the way products are designed and developed, offering rapid iteration, cost-effective testing, and versatile solutions for various industry needs. If you’re looking to enhance your product development process and bring your ideas to life quickly and efficiently, contact Formero today. Our 3D Printed Prototype services are designed to help your next project succeed. Reach out to learn how we can assist you in achieving your goals.

Author

Craig Alexander

Craig is a seasoned marketing professional with over 13 years of diverse experience in industries ranging from Asphalt Testing Technology to Environmental Sciences. His extensive background in B2B marketing, coupled with a deep understanding of complex technical fields like Power Tools, Solar & Battery Systems, and Emergency Lighting, uniquely positions him to bridge the gap between advanced manufacturing technologies and market needs. Craig leverages his comprehensive marketing skills to translate intricate manufacturing processes and innovations into clear, compelling narratives, helping businesses of all sizes succeed in both local and international markets.