How to Choose Metal for Metal Stamping

July 25, 2023

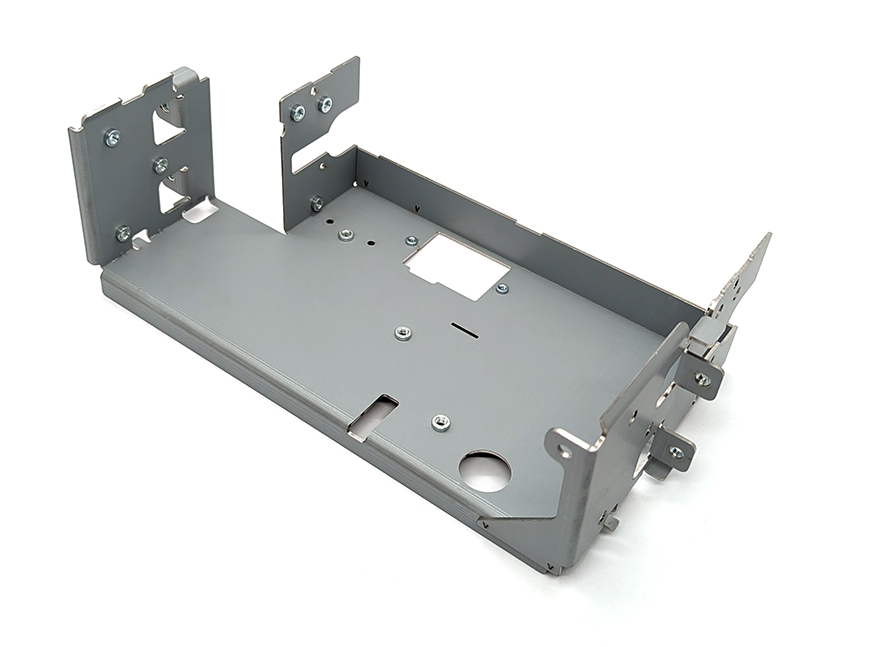

Metal stamping is a commonly used process when creating objects that primarily use metal in their production.

This method involves shaping and forming metal into different sizes and shapes using specialised tools and machines.

However, there are several types of metals that you can use for your projects. You may wonder what type of metal is best for your unique use case. Keep reading to discover some things you should consider when choosing a material for metal stamping.

7 Things You Should Consider When Choosing a Material for Metal Stamping

Choosing a material for metal stamping should involve careful consideration of the project’s needs and requirements. Here are seven things to keep in mind when deciding on a material for metal stamping:

1) Strength Requirements (for the finished part)

One of the most critical factors you need to consider when choosing a material for metal stamping is the strength requirements of the final product. This is because some materials are stronger than others, and you must choose the one that best suits your project’s needs. Consider the type of force and stress that will be exerted on the part to determine the level of strength it requires.

2) Aesthetics

The material finish is another important aspect to consider when choosing a material for metal stamping. If your project requires an aesthetically pleasing finish, you will need to select a metal that can be easily finished using methods like painting, powder coating, or polishing. Some materials have a natural sheen and require minimal finishing processes.

3) Geometry

The geometrical complexity of a part can also be a determining factor when choosing a material for metal stamping. Some materials are better suited to intricate shapes and designs, while others may not be able to maintain their shape when manipulated. It is essential to consider the type of design or shape you want to achieve and choose a material that can handle it.

4) Joining

Depending on the project, you may need to join two or more metal parts together. In such cases, it is important to consider the welding properties of different materials and choose one that can be easily joined with other components.

5) Corrosion Requirements

If your project will be exposed to extreme environments or elements that can cause corrosion, you need to consider the material’s resistance to corrosion. Some materials are more resistant than others and will be better suited for projects with these requirements.

6) Desired Weight

The weight of a finished part should also be taken into account when selecting a material for metal stamping. Some materials are denser than others, and if your project requires a lightweight component, you may need to choose a material that is less dense.

7) Formability

Lastly, consider the formability of different materials. Some metals are more easily shaped and formed than others, which can be an important factor if your project requires complex shapes or designs.

Why is it Important to Select the Right Material?

Selecting the right material is very important for several reasons:

- Cost: Different materials have different costs associated with them, and choosing the wrong one can be expensive.

- Product Use: The material used will affect the final product’s durability and functionality. Choosing the wrong material can result in a weakened or damaged part.

- Durability: Using the wrong material can result in a finished product that is not durable or long-lasting.

- Functionality: The material used will ultimately determine how well the part functions for its intended purpose.

- Design Requirements: Certain materials may not have the necessary properties to achieve a specific design or shape, resulting in an unsuccessful project.

How We Can Assist You At Formero

At Formero, we offer a wide range of metal materials for metal stamping, allowing you to choose the best material for your project’s needs.

Some of the materials available at Formero include Aluminium, Steel, Stainless Steel, Copper, Brass, Galvanised and Galvanneal Steel, Low Carbon Steel, Tinplate SPTE, Beryllium Copper (C 1720), Nickel Silver (C7521), Phosphor Bronze (C 5191), Spring Steel (SK7 and SK5), and Hot Rolled Steel (SPHC), just to name a few.

With our expertise, we can guide you in selecting the right material based on your specifications and requirements, ensuring a successful and cost-effective outcome. We also offer post-processing services to give your stamped parts a high-quality finish.

Conclusion

Metal stamping is more than just creating a part with any metal. It is just as important to select the right metal as it is to create the right design for your metal part. A great design with an unsuitable material can end up being low quality and even life-threatening, depending on the application of the part or product.

By considering some of the factors that we listed above, such as strength requirements, aesthetics, geometry, joining, corrosion resistance, weight, and formability, you can select the best material to meet your project’s needs.

At Formero, we are committed to providing high-quality materials and services to help you achieve your project goals. Contact us today to learn more about our metal stamping capabilities and how we can assist you in choosing the right material for your next project.

Author

Craig Alexander

Craig is a seasoned marketing professional with over 13 years of diverse experience in industries ranging from Asphalt Testing Technology to Environmental Sciences. His extensive background in B2B marketing, coupled with a deep understanding of complex technical fields like Power Tools, Solar & Battery Systems, and Emergency Lighting, uniquely positions him to bridge the gap between advanced manufacturing technologies and market needs. Craig leverages his comprehensive marketing skills to translate intricate manufacturing processes and innovations into clear, compelling narratives, helping businesses of all sizes succeed in both local and international markets.