What is 3D Printing? A Comprehensive Guide

May 24, 2017

3D printing, also known as additive manufacturing, is an innovative technology that has revolutionised various industries. It allows the creation of three-dimensional objects from digital models, layer by layer.

This comprehensive guide will explore the intricacies of 3D printing, its working principles, applications, materials, advantages, and promising future.

How 3D Printing Works

At its core, 3D printing involves the conversion of digital 3D models into physical objects through an additive process.

Unlike traditional subtractive manufacturing, where materials are cut away from a block, 3D printing builds up the object layer by layer, reducing material waste and enabling the fabrication of complex geometries.

Types of 3D Printing Technologies

Formero offers a wide variety of 3D Printing Technologies, with 11 3D Printers all located in Nunawading, Melbourne, Victoria. Our wide range of 3D Printers cover the following technologies:

- Selective Laser Sintering (SLS)

- Multi Jet Fusion (MJF)

- Stereolithography (SLA)

- Fused Deposition Modelling (FDM/FFF)

- Carbon Reinforced Fibre (CFR)

- Digital Light Processing (DLP/Figure 4)

- Colour Jet Printing (CJP)

Step-by-step Explanation of the 3D Printing Process

- Modelling: Designing the 3D model using computer-aided design (CAD) software

- Slicing: The 3D model is divided into horizontal layers to create a printable file (usually in STL or Step format)

- Preparation: The 3D printer is set up, and the appropriate printing material is loaded

- Printing: The 3D printer builds the object layer by layer, following the instructions from the sliced file

- Post-processing: After printing, some objects might require additional finishing or curing

Materials Used in 3D Printing

The material choices for 3D printing have expanded significantly in recent years. Here at Formero we offer over 17 different materials including:

- Thermoplastics: Nylon, PLA, ABS, PETG, and more

- Photopolymers: Resins used in SLA and DLP

- Composites: Reinforced materials for enhanced strength and properties

3D Modelling and Designing for 3D Printing

Creating 3D models requires specialised software, such as SolidWorks, Autodesk Fusion 360, or AutoCAD. These tools enable designers to bring their concepts to life in a virtual environment.

CAD and STL File Formats

CAD software generates designs in STL format, which divides the object into triangular facets, making it printable. This file format is widely accepted by 3D printers.

Tips for Designing Objects for Successful 3D Printing

To ensure successful 3D printing, designers should consider several factors:

- Wall Thickness Considerations: Designing with appropriate wall thickness ensures structural integrity

- Overhangs and Bridging: Minimising overhangs and bridging gaps reduces the need for supports

Once Formero has received your files, we will evaluate the need for support structures, and ensure that your parts are built using the optimal print orientation.

Applications of 3D Printing

Here are some of the fields where 3D printing has had an immense impact.

1) Healthcare and Medicine

- Concept Presentation Models: Precise and detailed models that accurately represent your design concepts.

- Customised Medical Devices and Prosthetics: Patient-specific medical devices, orthotics and prosthetics can be produced efficiently.

2) Aerospace and Automotive Industries

- Prototyping and Rapid Manufacturing: 3D printing accelerates the prototyping and testing phases of aerospace and automotive components.

- Lightweight and Complex Part Production: 3D printing enables the fabrication of lightweight, intricate parts for improved performance.

- High-strength, Lightweight Automotive Parts: Printing in technologies such as our Markforged FX20 gives designers the ability to integrate carbon fiber reinforcement for superior strength-to-weight ratios

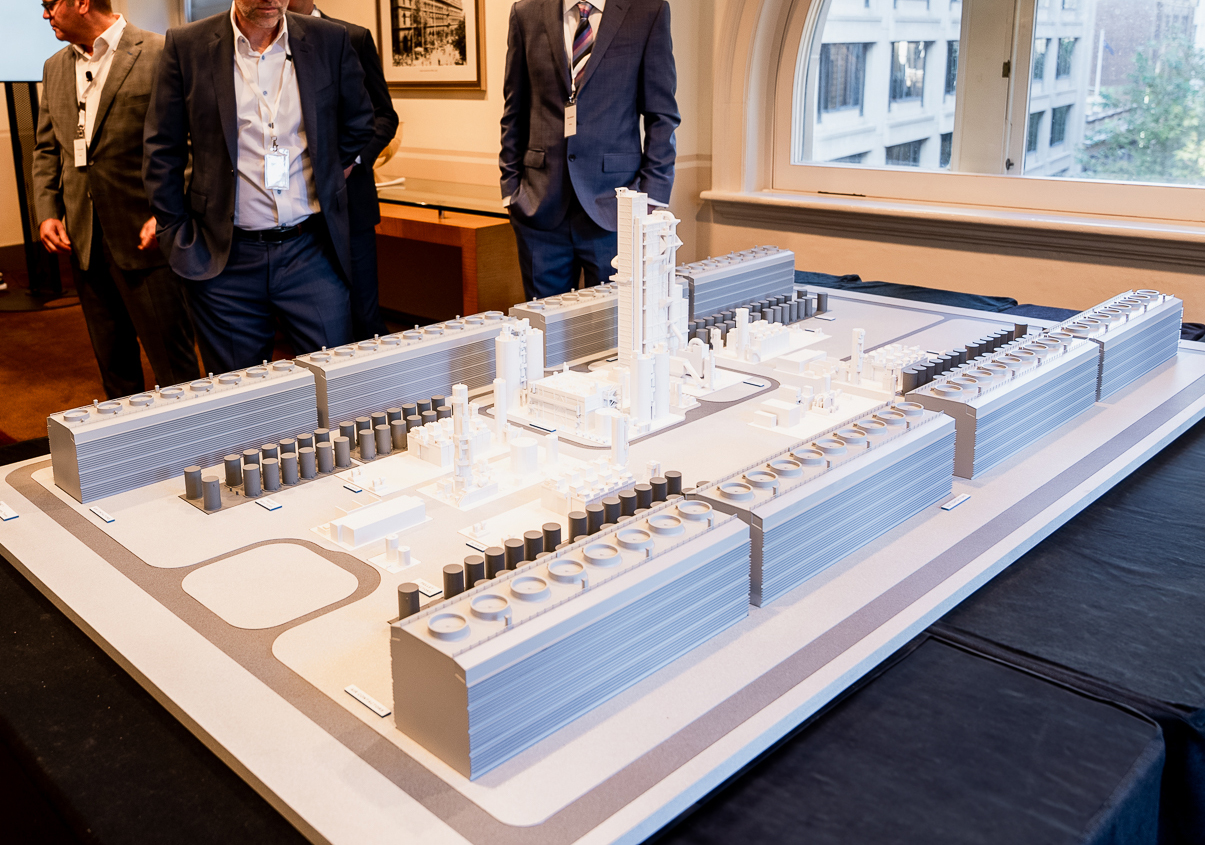

3) Architecture and Construction

- Rapid Prototyping of Architectural Models: Architects use 3D printing to visualise and refine their concepts quickly.

- 3D Printed Houses and Infrastructure: The construction industry explores 3D printing for cost-effective and sustainable building projects.

4) Education and Research

- Enhancing Learning Experiences: 3D printing introduces hands-on learning and better understanding of complex concepts.

- Scientific and Engineering Research Applications: Researchers use 3D printing to create prototypes and custom lab equipment.

5) Consumer Goods and Fashion

- Customised Products and Accessories: 3D printing allows personalised consumer goods and fashion items.

- 3D Printed Fashion and Jewellery: Designers leverage 3D printing to create avant-garde fashion pieces for movie props and alike.

Advantages of 3D Printing

Advantages

- Design Freedom and Complexity: 3D printing enables the production of intricate shapes and geometries impossible with traditional methods

- Faster Prototyping and Time-to-Market: Rapid iteration and testing reduce product development timelines

- On-demand Manufacturing and Reduced Inventory Costs: Objects can be printed when needed, reducing storage costs

- Sustainable and Eco-friendly Aspects: Material waste is minimised due to the additive nature of 3D printing

Future of 3D Printing

The future of 3D printing holds immense potential to disrupt industries, streamline production processes, and improve people’s lives with customised products and medical solutions.

Conclusion

3D printing has evolved from a niche technology to a powerful tool used in diverse industries. Its ability to transform digital designs into tangible objects has made it invaluable for prototyping, customisation, and innovation.

As technology continues to advance, we can expect 3D printing to play an even more significant role in shaping the future of manufacturing and beyond.

Frequently Asked Questions (FAQ): 3D Printing

What is the cost of 3D printing?

The cost of 3D printing can vary depending on several factors, including the material used, the technology selected, the size and complexity of the object, and any post-processing required.

Can I 3D print any object?

While 3D printing offers great design flexibility, there are some limitations in particular the size of the print and the material properties. More often then not, Formero will have a work around for most problems that arise. For example, large parts can be printed in sections and glued together with high precision. We also offer over 17 different materials so we are sure to have something that suits your requirements.

How long does it take to 3D print an object?

The time required to 3D print an object varies depending on its size, complexity, the chosen 3D printing technology and the post-processing that is required. Formero can have parts printed and ready for shipping in as little as two days.

Is 3D printing environmentally friendly?

3D printing definitely has eco-friendly aspects compared to traditional manufacturing methods. It generates less waste because it adds material only where needed, reducing material scrap and has material recyclability. Additionally, localised production through 3D printing can reduce transportation-related carbon emissions. You can learn more by reading our Embracing Sustainability: The Role of 3D Printing & Additive Manufacturing blog post.

Are 3D printed objects as strong as traditionally manufactured ones?

The strength of 3D printed objects depends on the chosen material and the printing process. Some 3D printing materials, such as HST, Onyx, Ultem & Carbon Fibre FR-A, can offer comparable, if not higher strength to traditionally manufactured parts. Formero’s team of experts can help you decide which technology and material is right for you.

How can I learn 3D modelling for 3D printing?

Learning 3D modelling for 3D printing is accessible to beginners with various online resources. There are numerous tutorials and courses available for popular 3D modelling software SolidWorks, Autodesk Fusion 360, AutoCAD and more. Practice and experimentation are key to mastering 3D modelling for 3D printing.

Author

Craig Alexander

Craig is a seasoned marketing professional with over 13 years of diverse experience in industries ranging from Asphalt Testing Technology to Environmental Sciences. His extensive background in B2B marketing, coupled with a deep understanding of complex technical fields like Power Tools, Solar & Battery Systems, and Emergency Lighting, uniquely positions him to bridge the gap between advanced manufacturing technologies and market needs. Craig leverages his comprehensive marketing skills to translate intricate manufacturing processes and innovations into clear, compelling narratives, helping businesses of all sizes succeed in both local and international markets.