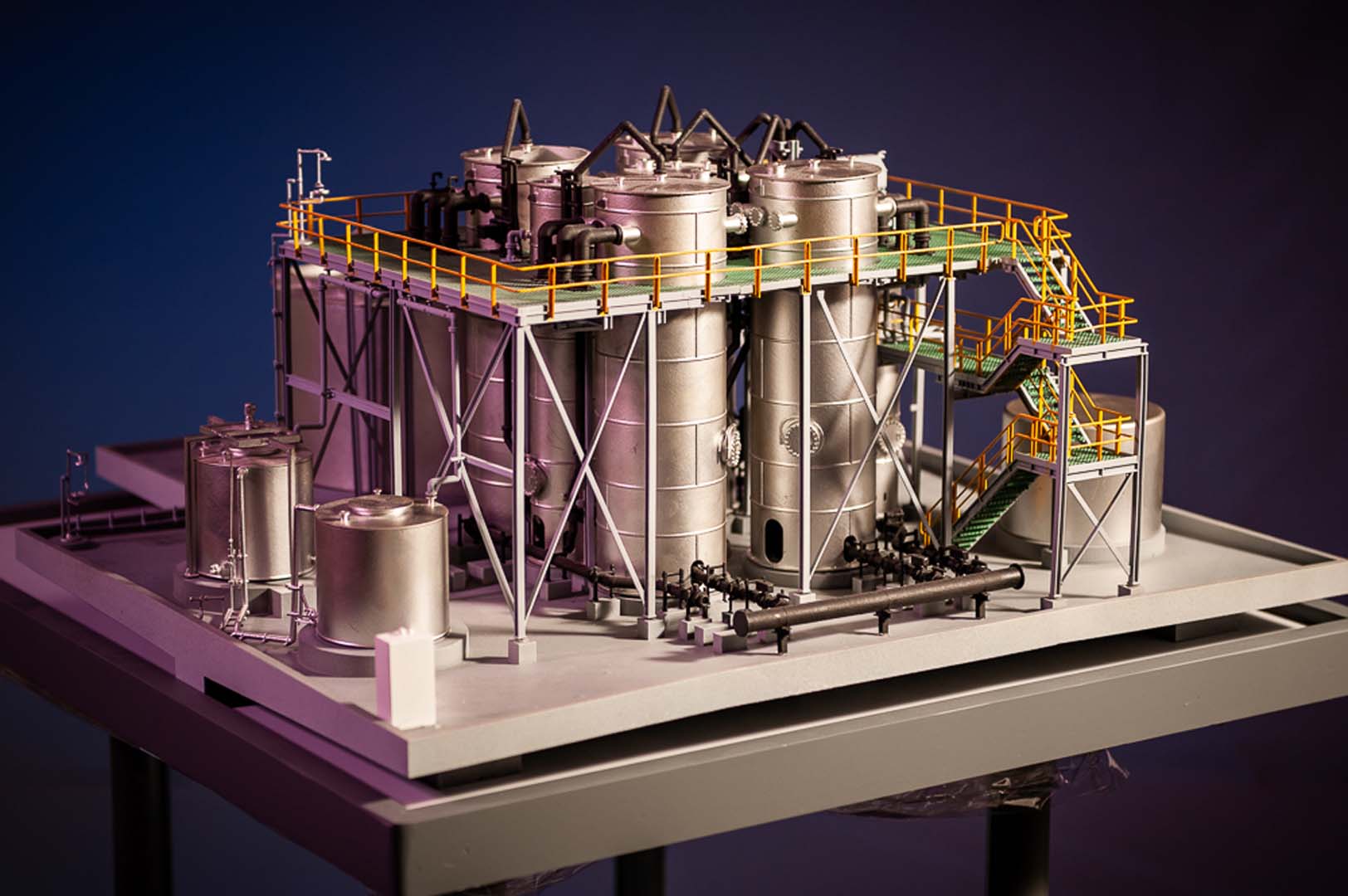

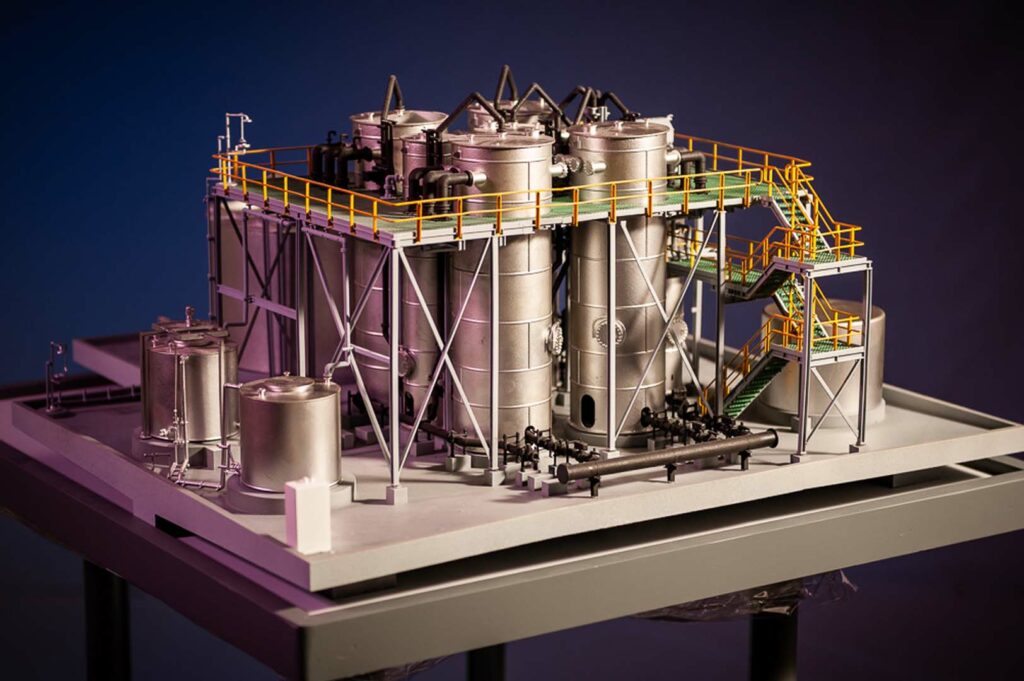

Architectural Scale Model

Challenge:

Clean TeQ is a leader in metals recovery and industrial water treatment. As part of their water treatment plant proposal, Clean TeQ required more than just computer renderings to communicate their waste water treatment plans.

To assist in their design proposal the team reached out to locally based additive manufacturing bureau, Formero ANZ, to supply a scaled 3D printed architectural scale model.

Traditionally, Stereolithography (SLA) 3D printing has been the most preferred method of creating scaled models, offering fine detail reproduction using epoxy-based material. However, this process requires high levels of post-processing to remove support structures. It also requires special care when transported, due to the brittle nature of epoxy resins.

Solution:

After evaluating the CAD, the experienced team at Formero decided HP’s Multi Jet Fusion (MJF) printing process would be able to provide a durable model capable of replicating the fine details and smooth finish suitable for painting.

With architectural CAD software usually the biggest bottleneck in getting from a drawing to a printable 3D model. Care was taken to ensure all features would successfully replicate. For CleanTeQ’s project, some sections were dimensionally adjusted, such as stairwells, pipes and railings so they’d successfully replicate in the 3D printing process.

Once printed, it was just a matter of removing the excess nylon powder with an air gun. It’s at this stage MJF 3D print process saved a lot of time, as architectural models are generally very detailed. Kathryn Hay, Technical Sales Specialist at Formero says, if we’d printed this model in SLA it would have been rather difficult removing the support structures and sanding all the surfaces to a smooth finish. MJF parts are naturally fairly smooth and allowed us to move onto painting the model fairly quickly.

Result:

While 3D printing buildings and architecture designs can create challenges of scale, Formero’s decades of experience meant the team was able to assist Clean TeQ with pre-print files and print a model that could easily be transported from place to place without risk of damage. Using MJF technology had the advantage of creating complex, robust models with a smooth finish, eliminating the need to hand finish with sandpaper.

For Clean TeQ, when it comes to a project proposal, a 3D print model helped their customer visualise the end result and engage at an earlier stage of the planning process.

Relevant Services.

Ready to speak with us?

If you have questions please feel free to contact us.

Other Case Studies.

3D Printing for Race Cars: Enhanced Cooling Efficiency

MMS needed to prevent overheating in their motors & inverters. The challenge was to create durable, heat-resistant parts that would manage thermal loads effectively.

Read MoreProject Flock’s Hybrid Manufacturing Approach

Through Formero’s Hybrid Manufacturing solution, Project Flock were able to bring their innovative Biomotion tail light to market.

Read MoreQuick Turnaround Architectural Models

Using SLA we 3D Printed Architectural Models in as little as 5 days for a carbon-capture plant, which extracts CO2 from the air, directly removing CO2 from the atmosphere.

Read More